Have you carried out a project in the baking industry and faced tough decisions, such as the type of flooring in your production area or the target temperature of your packaging room? Perhaps you now question the choices that were made? Or maybe you are about to start a project of bread, viennoiserie or pastry manufacturing and you are already asking yourself these questions? Or you are simply a professional in the baking industry and curious about the content and purpose of this article?

In any case, with a desire to share our technical expertise, we have created this article dedicated to the building facilities finitions in a production unit specialized in bread, viennoiseries, pastries, and other sweet or savory snacking products.

Hopi consulting is the only design office specialized in the baking industry. By focusing on a single sector, we are able to share high level expertise and ensure tailor-made solutions. Our global approach, covering equipment, utilities, and construction, provides our clients with know-how and experience that are always aligned with the specific requirements of the trade and the sector. We speak the same language and understand our clients’ challenges instinctively.

The topic of rooms facility finition levels is a good example. How often do we find ourselves in situations where our clients ask these familiar questions: which options should I choose for my floor coating, type of walls, and air treatment targets ? And how often do we encounter clients who regret their choices, often due to a lack of proper advice or bad cost-saving considerations?

This article does not aim to impose any specific choices for facility finishes, nor to compete with the missions of our construction partners or project managers. We are also fully aware that some finishing choices are like matters of faith, and debating them can be challenging… However, our goal is to share best practices from a sector we know thoroughly, helping guide choices toward the right options while avoiding common pitfalls and poor decisions.

These industry standards in the baking and snacking business are not dependent on project size: whether a small manufacturing workshop or a larger-scale factory, the challenges regarding finishes and target temperatures are very similar, if not identical.

Enjoy your reading!

Table of Contents

Raw materials unloading area

Functionality:

- Raw materials unloading area, mostly delivered on pallets, rolls, or carts, and in crates for fruits and vegetables.

- It is important not to overlook the cold chain for incoming fresh raw materials: butter, yeast, creams, eggs, cheese… Therefore, a cold unloading dock should be included, even if it also handles ambient raw materials such as flour, salt, and sugar, as well as packaging materials.

- If a large number of handling equipment as well as forklifts, electric pallet trucks, etc. is used, it is recommended to protect the base of the walls with concrete or stainless steel barriers, which act as bumpers and reduce the impact of collisions.

Ambient storage

Functionality:

- Raw materials storage on racks and shelves: flour, salt, sugar, mixes, milk powder, improvers, gluten, starch, canned fruits/vegetables.

- Flour silos when located inside the building.

- Finished products storage in cases of daily dispatch of breads and viennoiseries produced each night and ready for shipment.

- It is important not to overlook explosion risk regulations for powdered products. Avoiding torn bags and airborne dust is crucial in this regard, and proper ventilation of the storage area is essential.

- Even if flour is delivered at ambient temperature, it will keep better if the temperature is controlled, particularly if the room temperature does not exceed 25°C. However, there is no need to store it at cold temperatures unless it is to compensate for insufficient dough cooling during mixing (insufficient water cooling and/or air treatment). Storing flour at very low temperatures only serves to reduce the base temperature of the dough in the mixer.

- Powdered products and water do not mix well. The best cleaning techniques remain vacuuming, so it is not necessary to provide a resin or tiled coating in this area.

- Storage of baked finished products from the night requires careful control of temperature and humidity to ensure freshness. These considerations are detailed later in the section related to cooling and resting.

- If a large number of handling equipment (forklifts, electric pallet trucks, etc.) is used, it is recommended to protect the base of the walls with concrete or stainless steel barriers, which act as bumpers and reduce the impact of collisions.

Cold storage

Functionality:

- Raw materials storage: yeast, eggs, milk, creams, butter, cheese, chocolate, fruits and vegetables…

- Semi-finished products storage: dough, preparations, biscuits, savory fillings…

- Finished products storage: fresh pastry and snacking products.

- This area must be cleaned regularly for hygiene challenges. Therefore, it is necessary to provide insulated sandwich walls and a tiled or resin-coated floor, as well as a wastewater drainage system.

- Hygiene regulations, particularly sanitary approvals, require the separation of meat and other raw materials such as butter, eggs and cheese.

- Fruits and vegetables are often stored separately in a dedicated room due to odors, the presence of wooden crates, and soil or dust.

- For workflow efficiency, and even if temperature conditions are the same, it is preferable to separate incoming raw material stock from outgoing finished product stock.

- If a large number of handling equipment (forklifts, electric pallet trucks, etc.) is used, it is recommended to protect the base of the walls with concrete or stainless steel barriers, which act as bumpers and reduce the impact of collisions.

Frozen storage

Functionality:

- Raw materials storage: fruit purees, bakery products merchandise (bakeoff viennoiserie…) purschased to suppliers, backup baked breads, chocolate…

- Semi-finished products storage: dough, preparations, biscuits…

- Finished products storage: all bakery, viennoiserie, and pastry products.

- This area must remain dry to ensure proper operation of the ambient air treatment system. No water cleaning is recommended, so it is not necessary to provide a resin or tiled floor in this zone.

- To keep the room free of ice and frost, it is essential to prevent outside humid air from entering. When this warmer air comes into contact with the refrigerated environment, the moisture it contains accumulates as frost on the evaporator. Installing an air curtain at the room entrance is an effective solution.

- If a large number of handling equipment (forklifts, electric pallet trucks, etc.) is used, it is recommended to protect the base of the walls with concrete or stainless steel barriers, which act as bumpers and reduce the impact of collisions.

Packaging materials storage

Functionality:

- Packaging materials storage: cartons, labels, blisters, sleeves, …

- This area does not present any specific requirements related to the baking industry.

- The expected finish level is therefore basic and economical.

- However, it is advisable, even if it incurs a cost, to heat the room when it becomes too cold (threshold at 15°C), as packaging materials easily absorbs moisture from the air, causing technical issues when packaging processes are mechanized.

- If a large number of handling equipment (forklifts, electric pallet trucks, etc.) is used, it is recommended to protect the base of the walls with concrete or stainless steel barriers, which act as bumpers and reduce the impact of collisions.

Preparation and production areas

Functionality:

- Kitchen, preparation room, production area, make-up line zone…

- Any area dedicated to the production of semi-finished and finished products.

- These areas must be cleaned regularly for hygiene reasons. Therefore, insulated sandwich walls and a tiled or resin-coated floor should be provided, along with a wastewater drainage system.

- In bakery areas, vacuum cleaning is easier on this type of floor. At a minimum, the floor in the dough-mixing area should be protected due to the presence of dough residues, water, oil, and starter on the floor.

- Humidity is also an important factor, particularly in mechanized dough processes such as in bakeries and viennoiseries. Excessive humidity will cause stickiness.

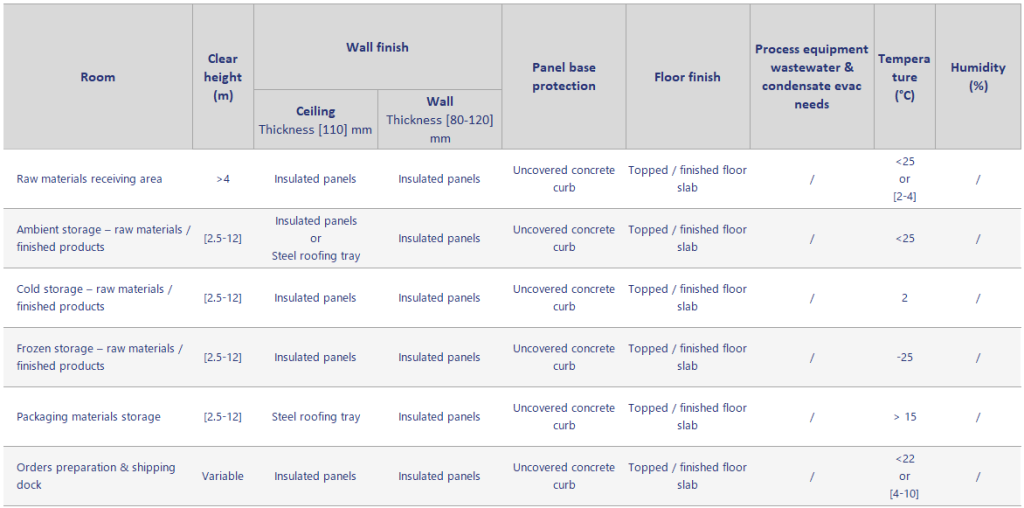

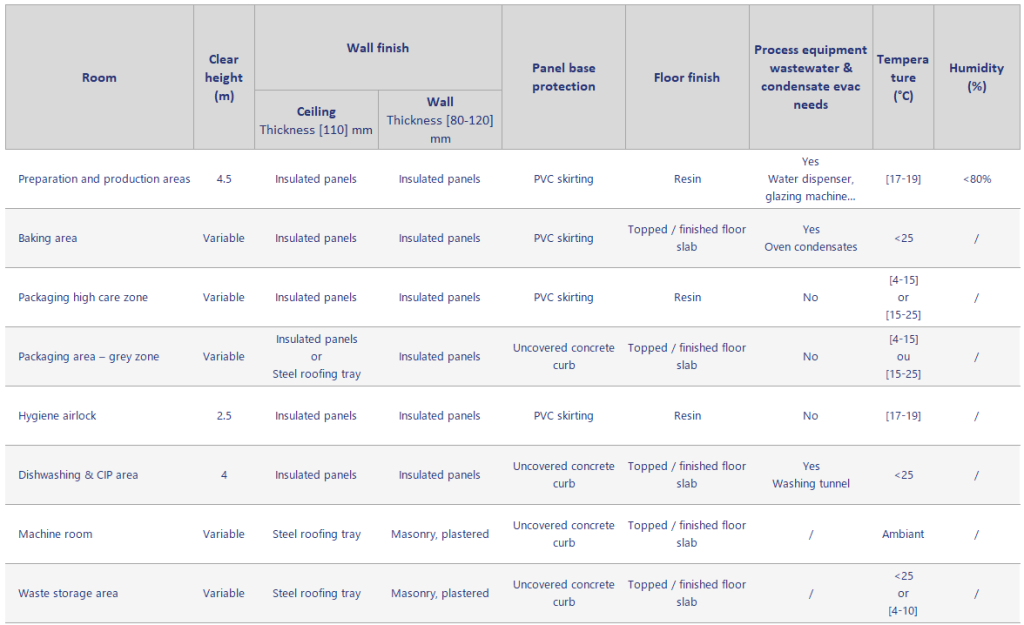

- Target temperature and humidity levels depend on the product range, so it is important to focus on each product type. The table below provides a summary of best practices.

Fermentation area

Functionality:

- The fermentation room (also called the proofing chamber) is a space that allows precise control of the fermentation of leavened dough, particularly by adjusting temperature and humidity levels.

- There are large-capacity fermentation chambers (holding several trolleys), but smaller units are also available for low-volume needs.

- This area is exposed to a highly aggressive environment due to fermentation vapors. It is essential to provide stainless steel wall surfaces to protect the integrity of all walls.

- This room must be cleaned regularly for hygiene reasons. Therefore, a tiled or resin-coated floor should be installed, along with a wastewater drainage system.

- Air treatment is fundamental, but this should be left to specialized process equipment suppliers for fermentation studies.

Baking area

Functionality:

- Baking of bakery and snacking products: breads, viennoiseries, biscuits, cakes, sponge cakes, filled pies (fruits jam/sugar/chocolate…), filled pies (chesse/ham/vegetables…)

- This area generates a lot of heat and must be ventilated with air renewal to remove excess heat from the ovens and baking processes. Process chimneys and hoods are essential. These rooms are often poorly ventilated, and temperatures can become very high.

- It is not necessary to protect the floor in this area with resin or tiles. Sweeping is generally sufficient for cleaning, except when baking filled products that may cause significant splashes on the floor.

- Baking rooms with high ceilings provide better working conditions for operators, as the confinement effect is reduced.

- Installing sandwich walls can be useful for weekly cleaning, but it is preferable to leave the building’s roof ceiling unprotected. A sandwich ceiling offers no real benefit and will quickly yellow, making the room appear dirty and poorly maintained.

Cooling or resting room

Functionality:

- Cooling and resting of hot baked bakery products.

- This area is a strategic zone for maintaining the quality of the finished product. Air treatment, temperature control, and humidity management are fundamental and highly technical parameters (more details can be found in our article on cooling).

- Insulated sandwich panels are recommended for thermal insulation. However, it is not considered necessary to protect the floor in this room; dry cleaning should be sufficient.

Packaging high care zone

Functionality:

- Packaging area for unpacked naked products, with high care hygiene requirements and long shelf-life considerations.

- This area is strategic in the baking industry, particularly for fresh packaged products. For items such as sandwich bread, buns, or brioche, analyses of contamination sources—and thus reduced product shelf life—have highlighted issues with air quality. For this reason, a high level of air filtration is recommended, including G4-H9-F13 filtration, and potentially additional ultraviolet treatment.

- Similarly, this room must be cleaned regularly for hygiene reasons, which requires insulated sandwich walls and a tiled or resin-coated floor, along with a wastewater drainage system.

- Target temperature and humidity levels depend on the product range, so it is important to focus on each product category (see table below).

Packaging area – grey zone

Functionality:

- Packaging area for pre-packed products intended to be placed into sleeves, cartons, etc.

- This area does not have specific requirements related to the baking industry.

- Since the products are already packaged, they are protected from external contamination.

- The key concern is temperature control to maintain the cold chain.

Orders preparation & shipping dock

Functionality:

- In the orders preparation area, finished products are organized and grouped according to different shipping formats: pallets, bins, roll carts, etc. Once orders are prepared by client or carrier, they are staged at the shipping dock for dispatch.

- This area does not have specific requirements related to the baking industry.

- It also does not require a finish suitable for wet cleaning since the products are already packaged.

- However, it is advisable to have a perfectly finished floor due to the heavy traffic of handling equipment. This ensures safer circulation, reduces wear on equipment, and minimizes the risk of accidents or product damage.

- If a large number of handling equipment (forklifts, electric pallet trucks, etc.) is used, it is recommended to protect the base of the walls with concrete or stainless steel barriers, which act as bumpers and reduce the impact of collisions.

- Depending on the product temperature targets and shipping methods, the order preparation area can be maintained in a dry environment, positive cold, or even negative cold, once again to preserve the cold chain.

Dishwashing area

Functionality:

- Washing of dirty equipment and utensils, storage of dirty items before washing, and storage of clean items after washing.

- This room has no specific requirements related to the baking industry. However, its design must integrate several key objectives.

- A dishwashing area must be designed with a clear one-way flow. A first zone must allow for the storage of dirty equipment and utensils coming from production. A second zone is dedicated to the actual washing process. And a third zone is used to store the clean items made available for production.

- These rooms must be cleaned regularly for hygiene reasons. Therefore, insulated sandwich panels and a tiled or resin-coated floor are required, along with a wastewater drainage system.

- Air treatment must also be properly designed, as this room generates potentially corrosive vapors. Special care must be taken regarding extraction airflow and make-up air. Ventilation ducts and accessories should be made of stainless steel rather than PVC to ensure long-term durability.

Waste room

Functionality:

- Storage of all types of waste: organic, cardboard, general industrial waste, returnable containers, glass…

- The valorization of waste is increasingly leading baking industry operators to manage a dough waste stream. To limit fermentation effects, it is crucial to maintain a controlled, low temperature in this area.

- For cleaning purposes, insulated sandwich panels are recommended. The floor should also be suitable for regular cleaning, so tiled or resin-coated, along with a wastewater drainage system.

Fire risk best practices and standards

Penetrations through fire-rated walls and sandwich panels

Challenges and requirements:

- Prevents fire spread and limits smoke propagation

- Maintains the functionality of fire safety systems

- Ensures regulatory compliance and personnel safety

- Concrete walls: Use certified firestop sealants or mastics to fill all gaps around cables and conduits.

- Concrete walls: Ensure the fire-rating of the wall (EI 60 or EI 120 minutes, etc.; EI = Integrity + Insulation, duration in minutes) complies with regulatory requirements and insurer recommendations.

- Sandwich panels: Ensure the fire-rating of the panel (according to NF EN 13501-1, European fire classification standard) complies with regulatory requirements and insurer recommendations.

- Preserve the integrity of safety cables (alarm, detection).

Minimum distance between sandwich panels and electrical equipment

Challenges and requirements:

- Prevents lights or fixtures from becoming fire propagation points

- Maintains the functionality of emergency lighting in case of fire

- Ensures effective fire protection for the rooms

- Ensures regulatory compliance and occupant safety

- Install lights and fixtures in authorized locations (wall or ceiling according to plan and fire-rating classification)

- Use lights and fixtures that are certified or compatible with fire protection

- Ensure that power cables comply with firestop penetrations

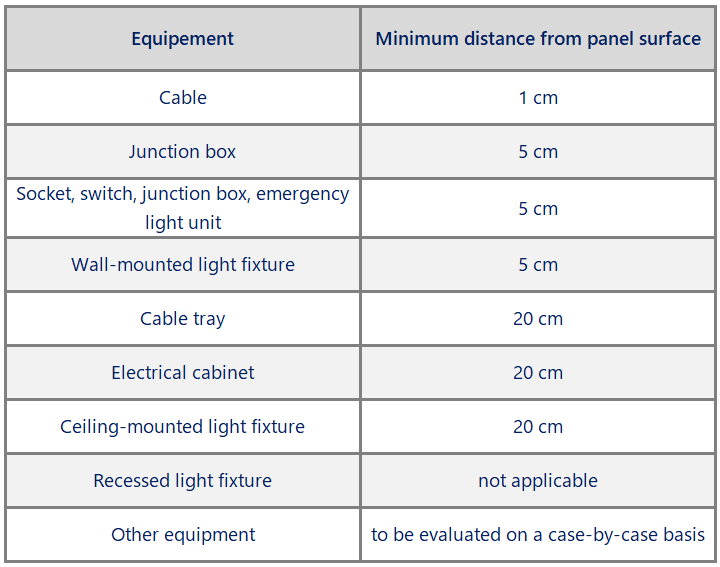

- Maintain minimum distances from combustible materials (see table below)

Hopi consulting standards

Conclusion

The success of a project in the baking industry is not limited to equipment choices or recipes: the design and the levels of rooms finitions play a key role in efficiency, safety, and product quality. Every decision—whether regarding floors, walls, or air treatment—must be carefully considered in light of the specific constraints of the industry and sector best practices. The impact of both good and poor decisions is far from negligible.

Through its industry expertise and daily experience in the baking sector, Hopi Consulting supports clients by anticipating pitfalls, optimizing technical choices, and ensuring long-term, tailored solutions. Sharing this know-how helps industry players make informed economic and technical decisions and build high-performance facilities that comply with baking sector standards.

Finishing choices are not secondary: they are a strategic and economic issue. “Doing it right the first time” is not an easy task, but it is the goal Hopi Consulting pursues, as it is the only way to avoid regrets, cost overruns, and daily inconveniences. Well-informed, each stakeholder can turn these technical recommendations into real success levers.

Hopi Consulting accompanies you in this process with tailored, independent technical support, 100% dedicated to the baking industry. To learn more, discover our solutions on our website.

This article was written by Hopi Consulting, engineering dedicated to the baking industry.

Discover more articles on the Hopi Consulting blog dedicated to the baking sector.