INTRODUCTION

Hopi Consulting’s blog wants to bring a fresh and neutral perspective to the technical solutions offered by equipment suppliers in the bakery industry. We have created these articles with the wish to promote the suppliers with whom we like to share projects, while always keeping in mind our will of independence and impartiality.

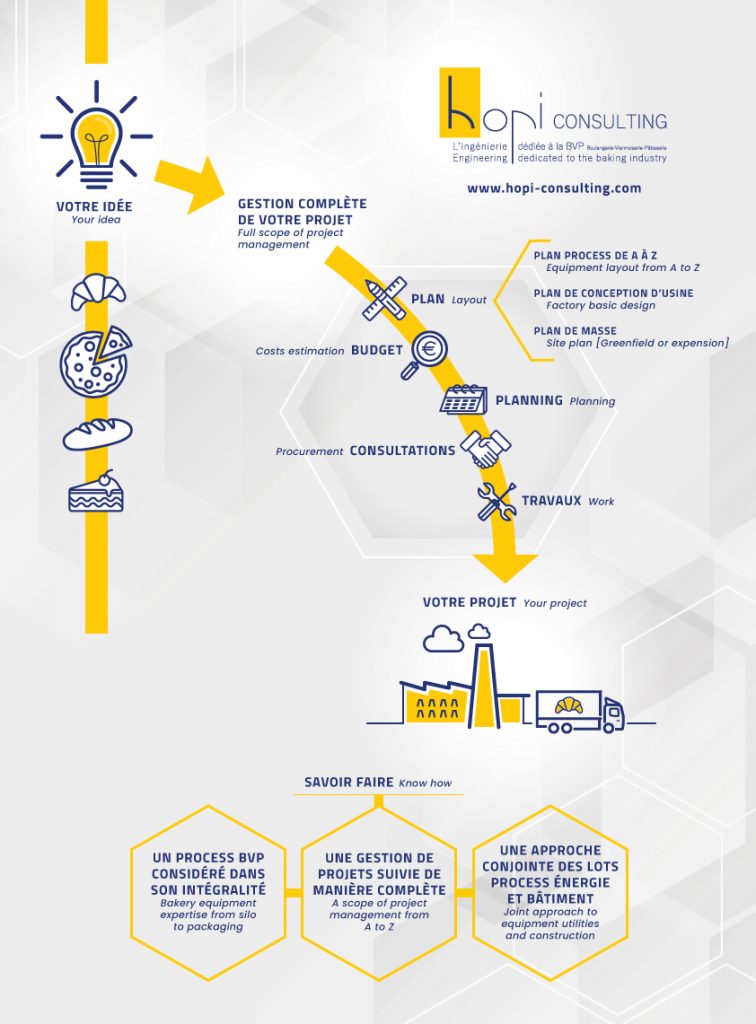

Take a tour to Hopi Consulting website and find innovative technical support and project management assistance. With a commitment to tailor-made solutions and baking industry expertise.

Baking is the art of interaction of living raw materials such as flour or yeast and natural activities as fermentation. Despite innovations and technical modernizations, it is still not possible to put under control from A to Z the baking manufacturing process. But still some options exist to bring help and assistance. Stephane Fjelddahl provides now this kind of technical support, we couldn’t imagine our blog without a focus on his new solutions.

Ronan Le Bourhis

Hopi Consulting

Hello Stephane, this is the first interview in our blog dedicated to the bakery industry and I am very happy to do it with you. You know that this blog focuses on technical innovation in the bakery industry. So how could we imagine our blog without speaking about what you are doing now ?!

First, could you introduce yourself and tell us more about your background ?

Stephane Fjelddahl

Falk Thermal

Thank you, Ronan, for considering me for this interview. I’m obviously very happy to kick off this new format for your blog.

My name is Stéphane Fjelddahl. For 18 years, I held a position as a project engineer at East Balt Europe, where I had the opportunity to be involved in numerous startups of bun bakeries across Europe. I also had the chance to manage a greenfield project in Aix-en-Provence, southern France, in 2010.

East Balt Europe was the main supplier of the buns used by McDonald’s before being acquired by Grupo Bimbo in 2017, which is the largest industrial bakery group in the world.

In 2015, I decided to venture into entrepreneurship by creating my own company, Mountdale. The business is similar to what I did at East Balt but not anymore limited to buns, as it encompasses all types of bread.

Ronan Le Bourhis

Hopi Consulting

And today, we all hear about “Falk Thermal” So tell me more about it ?

Stephane Fjelddahl

Falk Thermal

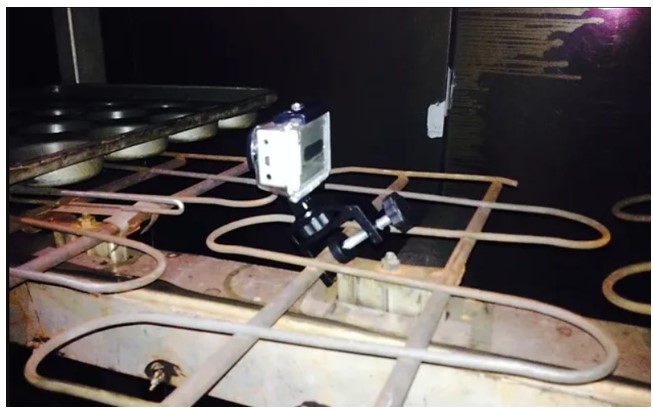

One of my early assignments in 2015 was related to a baking issue in a bun oven. The client may recognize himself. To highlight an excessive airflow problem, I used whatever means were available to me. It was my GoPro camera, gifted to me by my brothers for my 40th birthday, that came to my rescue!

I sent it through the oven, pointing it at a baking tray with breadcrumbs. All I had to do was watch the video and observe at which moment the breadcrumbs were blown away.

During the return journey, I promised myself to do the same thing but in a hot oven. That’s when a parallel project began, which has now culminated in Falk Thermal.

Ronan Le Bourhis

Hopi Consulting

Could you briefly summarize the field of activities of Falk Thermal ?

Stephane Fjelddahl

Falk Thermal

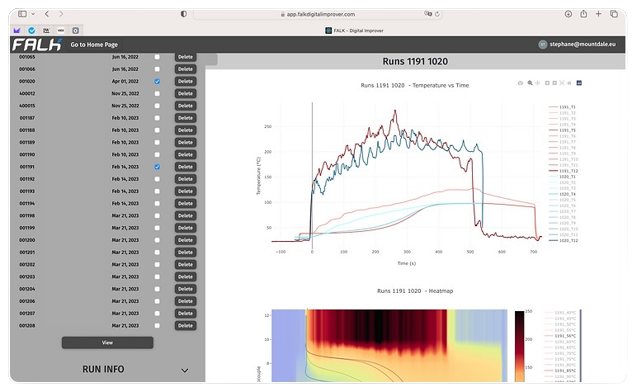

Falk Thermal specializes in obtaining and analyzing baking temperature curves. I assist players in the bakery industry in optimizing their baking processes by providing precise expertise on temperature parameters.

The FALK solution that I have developed collects temperature data during baking operations and analyzes them to identify opportunities for improvement and optimization.

I also provide personalized recommendations for adjusting temperature parameters, thereby improving the quality, texture, and flavor of bakery products. This can only be achieved through collaboration with the client’s baker or technologist.

“The FALK solution that I have developed collects temperature data during baking operations and analyzes them to identify opportunities for improvement and optimization.”

Ronan Le Bourhis

Hopi Consulting

So, what do these precious baking curves allow us to see ?

Stephane Fjelddahl

Falk Thermal

Baking curves provide a graphical visualization of key temperature parameters. The most used curve in baking is the one that comes from the center of the bread. It’s called the S-curve, and it is essential for defining the precise duration of each baking phase.

“Baking curves provide a graphical visualization of key temperature parameters.”

With this simple curve, it is possible to see the temperature of the dough at the beginning of baking, which corresponds to the proofing temperature, the oven exit temperature, the time to reach yeast deactivation, and the time to transform the dough into crumb. These data are essential when ensuring consistent bread quality.

I wanted to take the concept further by recording temperature curves from 9 different points within the bread: one reading point every 5 mm throughout the height of the bread.

Ronan Le Bourhis

Hopi Consulting

Did this result in a patent ?

Stephane Fjelddahl

Falk Thermal

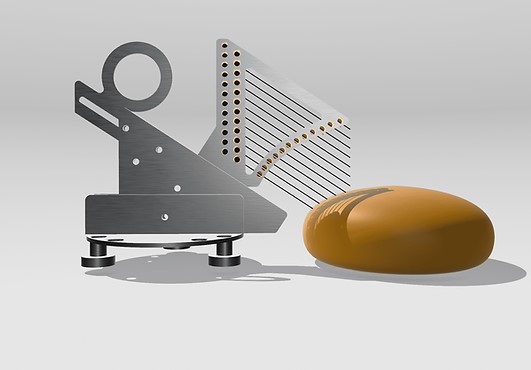

Yes, in 2021, I filed a patent for a device that allows the insertion of probes using a guided linear movement. This enables obtaining precise measurements at different points within the bread before it is placed in the oven and throughout the entire baking process. This device offers several advantages.

Firstly, it allows for the collection of more detailed and representative temperature data of the entire product, facilitating the analysis and optimization of baking curves.

“The reproducibility of temperature measurements is crucial for reliably evaluating and optimizing baking processes, and especially for obtaining comparable data.”

Additionally, data collection becomes repeatable, as the probes are always positioned at the same locations within the bread, regardless of the operator using the device.

The reproducibility of temperature measurements is crucial for reliably evaluating and optimizing baking processes, and especially for obtaining comparable data. I emphasize the importance of this notion of comparison.

Ronan Le Bourhis

Hopi Consulting

You gave a name, the FALK system, to your solution, insisting on the fact that the notion of comparison is a key point.

Where does this name come from ?

Stephane Fjelddahl

Falk Thermal

It’s a nod to Peter Falk, the actor famous for his role as Columbo. Indeed, analyzing a baking process requires a certain level of investigative work.

Ronan Le Bourhis

Hopi Consulting

Can you give us examples of improvements or successes achieved using your solution by clients and bakers ?

Stephane Fjelddahl

Falk Thermal

The use of the FALK solution, which consists of both hardware and software components, has allowed industrial bakers to achieve several improvements and successes.

For example, one baker was able to validate their production capacity increase by overlaying baking curves and observing that their action plan had minimal impact on them.

In another case, the FALK solution helped a client better understand their oven settings by conducting tests with extreme adjustments and then fine-tuning them. This approach allowed the bakery to regain valuable expertise, which, as you know, becomes increasingly important to maintain.

“The use of the FALK solution, which consists of both hardware and software components, has allowed industrial bakers to achieve several improvements and successes.”

The previous examples address specific issues. My solution has also been used by a bakery group aiming to standardize their baking processes. The quality of the final product should be consistent regardless of the production location. However, ovens are rarely identical, even when they come from the same supplier.

In fact, one observation I’ve made is that there is a tendency to adjust recipes to fit the oven, whereas it should be the opposite – the oven should adapt to the products. Unfortunately, once an industrial oven is installed, it remains unchanged for the next 20 or 30 years.

Ronan Le Bourhis

Hopi Consulting

Could you explain the way you proceed and describe what kind of missions your are able to carry out ?

Stephane Fjelddahl

Falk Thermal

To select the type of sensor and its placement within the bread, I use empathy. I put myself in the bread’s position, seeking to understand its sensations during baking. To sense the heat from the bottom, a temperature sensor positioned between the dough and the baking tray is appropriate. To perceive the energy received by the top of the bread, which contributes to its coloration, a heat flux sensor is more suitable.

I also wanted to bring an innovative touch by using soft materials for the thermal barrier, which is necessary to protect the electronics. A soft solution is much lighter and has less thermal inertia.

“I also wanted to bring an innovative touch by using soft materials for the thermal barrier, which is necessary to protect the electronics.”

Ronan Le Bourhis

Hopi Consulting

Stephane, to conclude, what types of clients and what business for Falk Thermal ?

Stephane Fjelddahl

Falk Thermal

I would be remiss if I didn’t focus on developing a solution for the emblematic product of my adopted country: la baguette ! A solution tailored for hearth ovens is currently under construction.

I also believe that the role of starch deserves further attention. Through specialized press, I discovered the thesis* of Dr. Timothée Gally, who, during his doctoral studies in food process engineering, worked on ohmic heating baking. The role of starch is omnipresent in his research. We are exchanging ideas on this topic, and a specific sensor could potentially emerge. This could be of interest to pre-baked bread or gluten-free product manufacturers, for example.

Furthermore, I see significant value in working collaboratively with research laboratories and ingredient suppliers. Together, we could leverage their expertise in ingredient properties and the science of baking. This collaboration would enable us to develop comprehensive solutions that meet the evolving needs of bakers.

Moreover, my solution could also be used to study energy consumption related to ingredients and production line parameters. By bringing together bakery industry professionals and the analytical power of laboratories, we would achieve a holistic and innovative approach to the bakery industry.

* “Etudes expérimentales et numériques du procédé de chauffage ohmique appliqué à la panification”

Thèse n°2017ONIR102F – Dr Timothée Gally

(Note: The mention of Dr. Timothée Gally’s thesis is a fictional reference for illustrative purposes.)

CONCLUSION

This article, in an innovative interview format, aimed to introduce Falk Thermal, and the solutions to put under control baking parameters regarding bakery products baking step.

Hopi Consulting likes to highlight partners we feel in line with our philosophy. Stephane is a good example, dedicating his efforts and innovations to the baking industry sector.

For more information about Falk Thermal and much more, please visit the website :

This article was written by Hopi consulting. Our motto : engineering dedicated to the baking industry ! Discover more articles on the Hopi Consulting Blog dedicated to baking industry.

Hopi Consulting brings new technical support solutions for a complete project management of your industrial project in bakery ! Let’s get in touch to discuss it !