We could begin this article with the following question: How do you choose between modernity and tradition?

The baking process is based on ancestral and fundamental principles such as gluten texturing during kneading, sugar fermentation during proofing, or starch gelatinization in the oven. These principles are key steps and technical constraints that cannot be challenged.

However, the means of achieving and mastering these results have evolved over time thanks to human innovation and the modernization of processes. These advances are naturally linked to mechanization, which relieves manual labor through automated operations—the kneading stage with a mixer being the most evident example. But progress extends far beyond this in the Bakery, Viennoiserie, and Pastry sector, including areas such as information management (automation, traceability, supervision) and energy (consumption optimization, specific energy solutions, etc.).

These advances have made the manufacturing process of BVP products more productive in order to meet ever-growing demand.

And what about quality? It hasn’t been forgotten, because products remain indulgent goods where the pleasure of consumption is never far away. These modern advances also influence the quality aspect of the products. This is true of the innovations discussed in this article, which focus on the cooling stage of products. In fact, you’ll discover that vacuum cooling has a notable impact on the appearance of products such as viennoiseries or bread, as well as on their shelf life.

Many thanks to Mickael Fléau and Thierry Le Garrec for their contributions to this article.

Enjoy your reading!

Cooling in the baking process

Cooling after baking is a key step that takes place after the products (bread, viennoiseries, pastries, etc.) are baked. It involves lowering the temperature of the baked goods in order to stabilize their structure and ensure their final quality.

But we now understand that this stage is also crucial in terms of product moisture: during this phase, the water present in the bread naturally migrates from highly concentrated areas (the crumb) to drier areas (the crust and ambient air). This migration directly impacts the quality of a baguette or croissant, particularly in terms of crispiness and shelf life.

It is more accurate to speak of “moisture release” since the key issue involves the temperature–humidity balance.

Here are the benefits of mastering the cooling stage in baking:

Better crispiness or softness

Improved consistency and homogeneity of the products

Enhanced appearance

Reduction of microbiological risks

Improved shelf life and longevity

Reduction of microbiological risks

Improved shelf life and longevity

Prevents condensation in bags

Facilitates slicing operations

Cooling Technologies

Several solutions are now available for cooling BVP products.

The choice of one solution over another can be influenced by:

- The budget

- Production capacity

- Available space

- The challenges and desire to control quality

- And, let’s be honest, the lack of knowledge about all the solutions available on the market.

Setting aside the most basic form of cooling, which consists of letting the products cool in ambient air, we will present the two current cooling technologies in bakery industry:

BY MECHANICAL COOLING: This is the principle of air conditioning that we are familiar with, used to control the temperature in our offices or refrigerators. The process involves refrigeration cycles of condensation and evaporation of a refrigerant to cool the surrounding air.

BY VACUUM: This principle involves lowering the air pressure in the chamber where the products are located, causing the products to cool down.

Static Cooling in Ambient Air

This is the most traditional cooling method. The products, stored on trolley racks or shelves, are left to cool naturally in the open air. As a result, the air is not controlled for cooling.

Examples of storage areas include:

- In the production room’s ambient air

- In circulation corridors

- Outdoors

Advantages :

- Simple and cost-effective (no specific equipment required)

Disadvantages :

- High floor space requirement and cluttered work areas

- Relatively long cooling time

- Irregular cooling since the room air is not dedicated to this step

- Cooling inconsistency depending on weather and season

- Difficulties cooling during hot periods or near ovens

- Difficulty evacuating humidity during cold periods

- High risk of microbiological contamination

- Feeling of being subject to uncertainties and lacking control over this step

Static Cooling with Air Conditioning

In this situation, the products, placed on racks and trolleys, are stored in chambers or tunnels where the air is now controlled.

The air is treated—it passes over exchangers and undergoes a circulation rate that allows for:

- cooling via a refrigeration system

- fine temperature adjustment through an additional heating cycle

- humidity adjustment via the addition of steam or water

This solution ensures consistent performance year-round, regardless of weather fluctuations.

Airflow management (temperature, intensity, direction…) is a key parameter for even more efficient cooling: by directing the air against the product flow, quality and energy optimization can be ideally achieved.

Two types of solutions are available:

Cooling tunnel: The trolleys are placed one behind the other. FIFO (First In, First Out) is perfectly maintained with distinct entry and exit points.

Cooling chamber: The trolleys are placed in a room that is loaded and unloaded from the same access point. The capacities of these chambers vary from one to several trolleys.

Advantages :

- Temperature and humidity control and management

- Reduced cooling time compared to ambient air cooling

- No weather-related impact on the cooling stage

Disavantages :

- High energy and installation cost

- Requires regular maintenance of equipment (refrigeration units, evaporators, etc.)

- Requires good knowledge of the product to adjust parameters (temperature, humidity)

Continuous cooler with air conditioning

In the industry, cooling has been adapted to continuous flow production. The solution is therefore a combination of a mechanized system for transporting the product and an air conditioning system to control the temperature and potentially the humidity.

Spiral cooler

The most commonly used mechanized solution is the spiral, which, with minimal floor space, allows for significant resting time of the product. Once the product has passed through the spiral, it continues its flow directly toward the freezing or packaging stage.

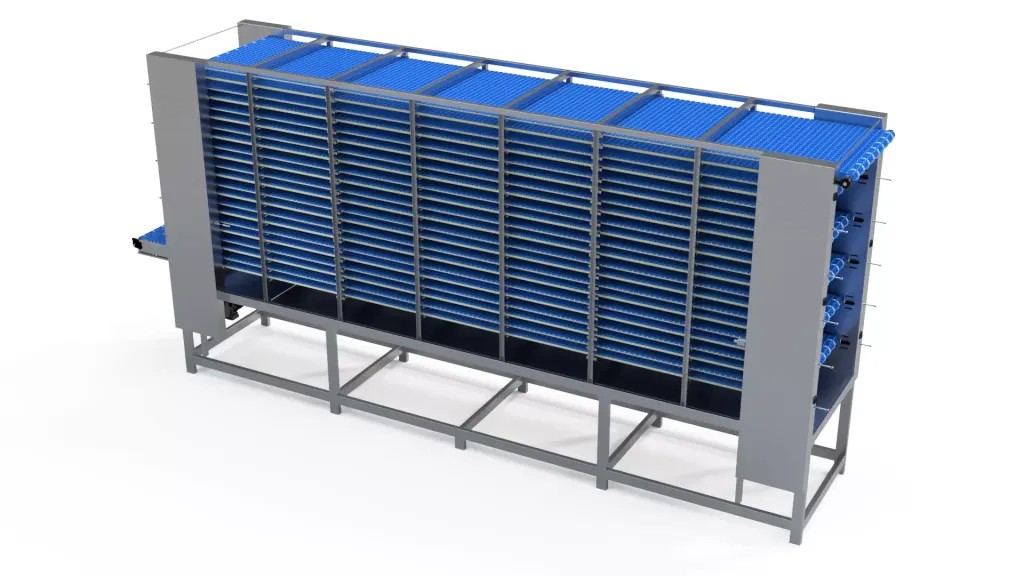

Multi-level belt cooler

The products move horizontally on one of the levels of the system. At the entrance, the different levels are fed via an elevator, and at the exit, they are collected using a lowering system.

Historically, these mechanized elements were installed openly within the production area. The cooling of the products relied on the air conditioning of the room, and the process was not highly optimized.

Today, the combined solution of mechanization and controlled climate offers even more consistency and optimization. In this case, the transport solution is enclosed in an insulated casing, similar to a freezer, to confine the air dedicated to the cooling process. This solution allows for precise control over the temperature and cooling targets of the products.

Today, hygiene concerns are added to thermal objectives. By adding a range of filters and other tools, such as ultraviolet systems, the cooling air is purified. The impact on product quality, especially their shelf life, is significant.

Advantages :

- Solution adapted to continuous processes and high production speeds

- Fine control of temperature and humidity of the environment

- Limited floor space requirement

- Ability to purify the air for quality assurance

Disadvantages :

- Installation and operating costs

- Difficulty in setting parameters depending on the products

- Cleaning challenges and hygiene and contamination concerns

Vacuum cooling

This solution competes with the traditional method using air conditioning.

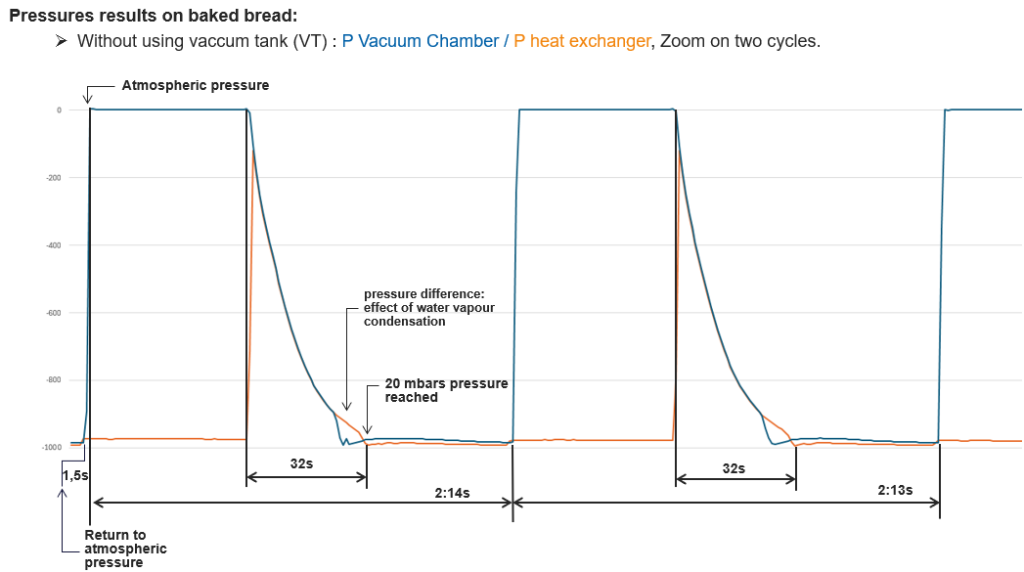

The principle involves placing the products in a closed, airtight chamber where the ambient pressure is reduced. This drastic reduction in pressure within a constant volume causes part of the water contained in the product to evaporate. In summary, this is the production of cold through a transpiration phenomenon. The temperature drop inside the product is extremely rapid.

As a result, water migration is limited due to the very short cooling time.

Note: Vacuum cooling is particularly suitable for highly hydrated doughs.

Similar to traditional cooling principles, the vacuum cooling solution adapts to both processes:

- Discontinuous principle: products are placed in a chamber capable of holding 1 or 2 trolleys. The cooling process is static.

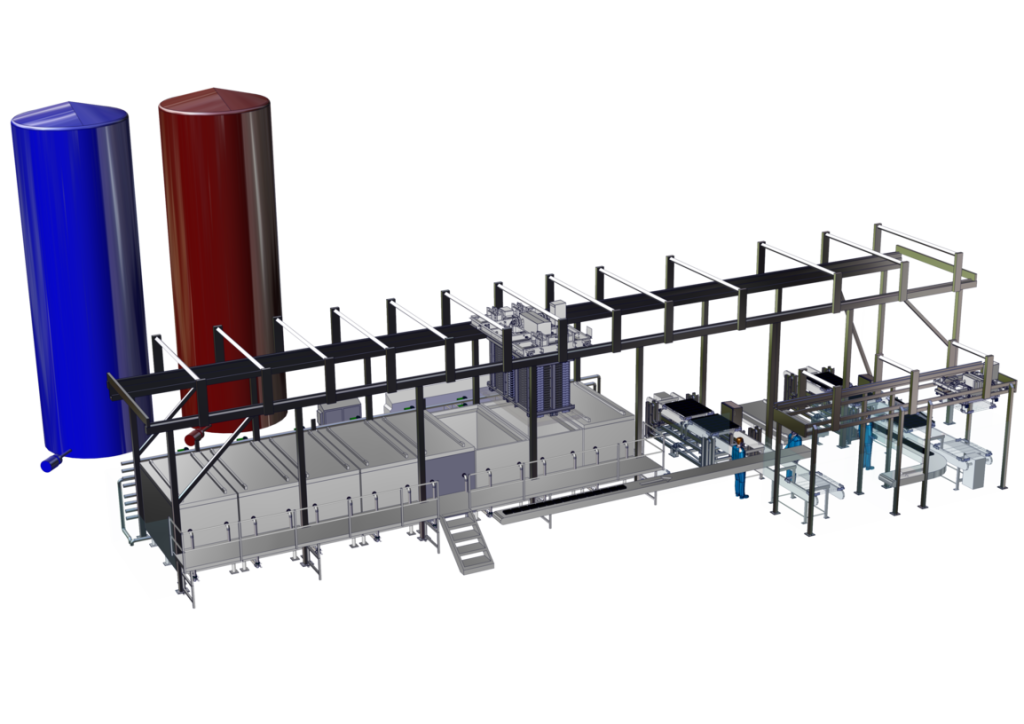

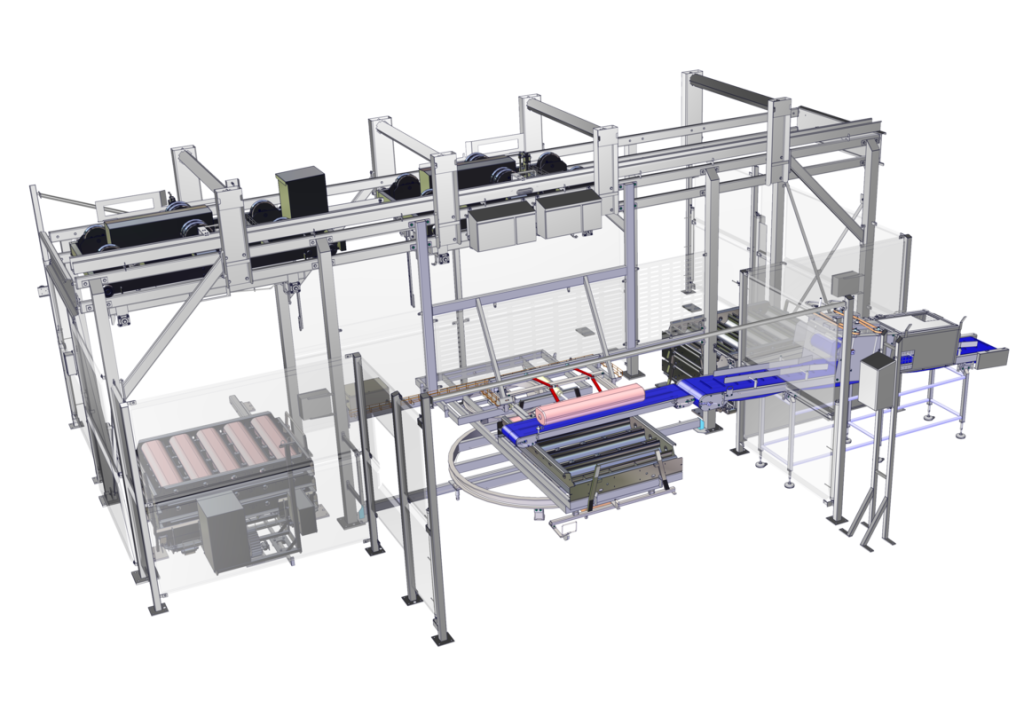

Continuous principle: It allows for the treatment of an uninterrupted flow of products. This presentation introduces the company Armor Inox, which offers this type of equipment.

Advantages :

- Extremely fast cooling time (a few minutes)

- Reduced microbiological contamination risk due to the very short time

- Preserves optimal volume and texture

- Very small footprint

- Reduction in cooking time, energy

Disadvantages :

- Less traditional process compared to natural or air-conditioned cooling

- Process not suitable for products with low moisture content

Our research shows no significant difference in terms of purchase or operating costs compared to air-conditioned technology.

A vacuum cooling project with ARMOR INOX

Presentation of the Middleby Group & Armor Inox

Key Figures:

- Founded: 1888

- Employees: Over 10,000 worldwide

- Headquarters: Elgin, Illinois, USA – Global presence

- Revenue: Over $4 billion

- Export: International operations in more than 100 countries

- Facilities & subsidiaries: Numerous production sites and specialized brands

MIDDLEBY is a world-renowned industrial group, and a leader in the design, manufacturing, and marketing of equipment for the foodservice, bakery, retail, and food processing industries.

The company brings together several specialized brands, covering the full range of professional needs — from baking to industrial process automation.

Below are a few of the brands under the MIDDLEBY group:

Since its creation, MIDDLEBY has established itself as a key player thanks to its constant innovation and its ability to integrate cutting-edge technologies into its equipment. Its wide range of solutions helps optimize food production while ensuring quality and performance.

Among its many specialized subsidiaries, MIDDLEBY has included Armor Inox since 2011, a recognized expert in industrial solutions for thermal processing and continuous baking.

Some key figures:

- Founded: 1972

- Staff: Around 100 employees

- Location: Mauron, Brittany, France

- Revenue: Over €25 million

- Export: International clients in more than 50 countries

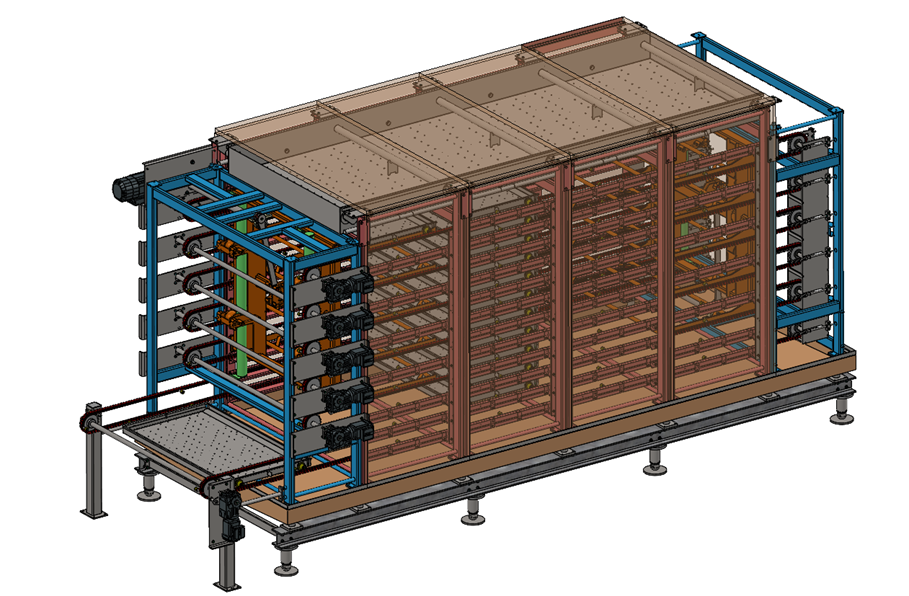

A subsidiary of the MIDDELBY group, Armor Inox specializes in industrial equipment dedicated to baking, cooling, and thermal processing of food products. The company is internationally recognized for its expertise in continuous baking lines and vacuum cooking systems using basins—a process particularly well-suited for the industrial production of meat products and ready meals.

Thanks to its know-how and patented technologies, Armor Inox supports manufacturers in optimizing their processes, ensuring high performance, optimal product quality, and energy efficiency.

Before exploring its solutions in more detail, a word on the origin of its name:

“Armor” refers to Brittany, the company’s region of origin, and “Inox” highlights its expertise in the design of stainless steel equipment, widely used in the food industry.

Focus on Armor Inox’s Technical Offering

Armor Inox offers innovative industrial solutions for baking, cooling, and production flow management in the food industry. Its expertise is based on high-performance technologies tailored to meet the requirements of industrial producers.

1. Continuous baking systems

✔ Immersion baking: a baking solution designed for various processes and batch modes of use.

✔ Continuous baking: a continuous process ensuring homogeneous production, suitable for high throughput.

2. Cooling and thermal management systems

✔ Rapid cooling in cold water tank: ensures controlled temperature reduction after baking, optimizing product preservation.

✔ Immersion or water shower cooling: suited for industrial needs to meet sanitary standards and improve productivity.

3. Automation and flow management

✔ Conveyors and handling systems: facilitate the transport of products throughout the process.

✔ Automatic loading and unloading systems: reduce manual handling and optimize production rates.

✔ Integrated cleaning solutions: ensure hygiene compliance with food industry standards.

Armor Inox designs custom equipment to meet the performance, hygiene, and efficiency requirements of industrial clients.

Implementation of vacuum cooling in a bakery workshop

Project input data:

- Small bread rolls [50-80] g

- [500-600] kg/h

- Batch: [240-300] rolls

- Baking time: 20 minutes

The completed and implemented project involved cooling a continuous flow of small 70g bread rolls. The products were taken in charge at the exit of the deck oven to be cooled before packaging.

Key points of the project:

- Average product temperature before cooling: 97°C

- Average product temperature after cooling: 21°C

- Cycle time: 2 minutes

Conclusion

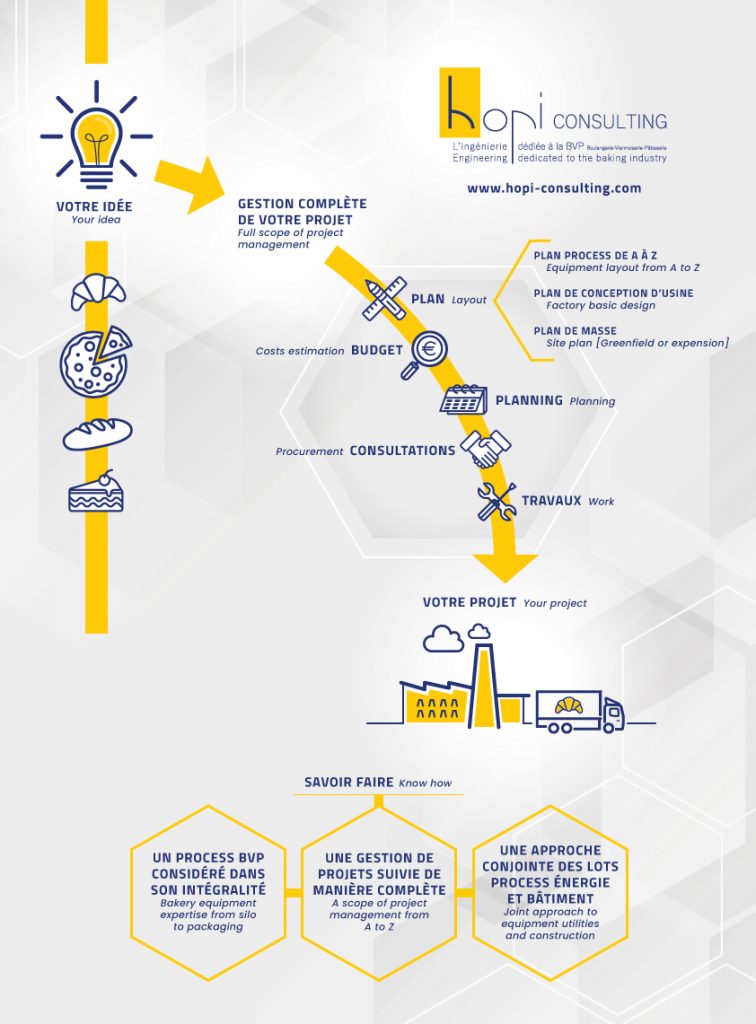

This blog aims to clarify the technical solutions offered in the bakery, viennoiserie, pastry and snacking sectors.

Cooling is a crucial step that drives fundamental issues in terms of quality and profitability. Therefore, it was essential to focus on current solutions, including vacuum cooling.

The best example was to present this bakery case study with ARMOR INOX, the company behind the project and realization. If you’d like to learn more about the MIDDLEBY group and ARMOR INOX, feel free to explore their website.

The technical choices in a baking industry project are numerous, with both advantages and disadvantages. To make the best choice, it’s crucial to start with the need and then associate it with the right machine, not the other way around. Hopi Consulting supports you in this process by offering tailored, independent technical guidance in a 100% baking industry approach. Discover our technical support solutions on our website.

So, what about you? What type of cooling do you prefer?

This article was written by Hopi Consulting, the engineering dedicated to Boulangerie, Viennoiserie, Pâtisserie. Discover more articles on the Hopi Consulting blog dedicated to bakery industry.