Have you ever heard, and rightly so, that bakery industry processing scope treats a live product? Which manufacturer will contradict me when I say that it is so difficult to control the impact that external conditions have on productions, whether human, material or environmental? Is this is a perfect introduction to the industrial challenge which consists in voluntarily modifying the environmental air parameters to optimise certain key stages of the bakery process such as fermentation, cooling after the baking stage or freezing?

This article focuses on the techniques and challenges of controlling the treatment of process environments in the bakery industry. Today, it is no longer a question of heating the air in an oven or cooling the air in a deep freeze box, only taking into account the “time/temperature” couple. The situation and the technical solutions have developed considerably and merit the time taken to write this article. By focusing on the company, CLAUGER, you will become more familiar with it and discover its field of activity in relation to this subject.

I am Ronan Le Bourhis, Founder of Hopi Consulting. I have created these articles with the desire to clarify bakery processing by highlighting suppliers with whom I like to share projects, always keeping in mind my desire for independence and impartiality.

First of all, thank you to David Huffschmidt from the CLAUGER company for his help in writing this article.

Historically very empirical and based almost exclusively on an experimental background, the management of process environments in baking is now much more theoretical and technical. The search for industrial productivity and the market’s demand for a regular product are the two main reasons.

KEY PARAMETERS

It is impossible to start this article without immediately introducing the key parameters or real levers of action for good management of the atmosphere and conditions that you wish to impose.

1- TEMPERATURE :

This is the criterion that comes to everyone’s mind. Temperature is a physical quantity, in everyday life, it is related to the sensations of hot and cold, resulting from the heat transfer between the human body and its environment. In physics, it is defined in several ways, but mainly as an increasing function of the degree of thermal agitation of the particles. The most common temperature scale around us is the degree Celsius scale.

This is the criterion that comes to everyone’s mind. Temperature is a physical quantity, in everyday life, it is related to the sensations of hot and cold, resulting from the heat transfer between the human body and its environment. In physics, it is defined in several ways, but mainly as an increasing function of the degree of thermal agitation of the particles. The most common temperature scale around us is the degree Celsius scale.

2- HUMIDITY :

Hygrometry? Humidity? Steam?

Simply and to understand: the ambient air is composed of water in the form of a gas called water vapour. Humidity is a common term: it is the amount of water vapour in the air. Hygrometry is a value that corresponds to the percentage of air saturation contained in humidity or water vapour (75% in the room where I am writing this article for example).

3- AERAULICS :

Aeraulics is the branch of physics that deals with the study of airflow and its applications. There are many applications, but the ones we are interested in are in ventilation and air conditioning.

Knowing these key parameters is necessary but it is not enough,

they still need to be mastered…

Here are a few words of caution to help you take stock of the complexity of the issues inherent in controlling the climatic conditions of these process environments in bakery processing.

A living product :

What could be more complex than attaching notions of reproducibility to a product that never reacts perfectly in the same way… It completely depends on the environmental conditions that are imposed on it and yet its reactions are sometimes unpredictable.

What could be more complex than attaching notions of reproducibility to a product that never reacts perfectly in the same way… It completely depends on the environmental conditions that are imposed on it and yet its reactions are sometimes unpredictable.

Target and actual value :

As soon as the technical process is based on instrumentation and measurement elements, the issue of accuracy and repeatability of the information measured takes on a considerable role. It comes from the essential notions of calibration and reliability of these measuring instruments (probes, sensors, etc.).

Monitoring precision :

As soon as the technical process is based on instrumentation and measurement elements, the issue of accuracy and repeatability of the information measured takes on a considerable role. It comes from the essential notions of calibration and reliability of these measuring instruments (probes, sensors, etc.).

Impact of dust & aggressive environments:

Air treatment management in bakeries are made even more complex because of sources of contamination that can potentially lead to corrosion of the equipment, such as flour dust in the air, but also the broken crusts of products, such as bread. The hot fermentation environments in the presence of yeast also contribute to these very demanding environments for the equipment (from visible wear and tear of the frames to drifts in performance due to the clogging of heat exchangers, air diffusion ducts, etc…).

Multifactorial study :

This is probably the greatest difficulty linked to this topic – the treatment of bakery processing environments : the fact that no key parameter (T°C, humidity, etc.) can and should be considered in isolation. The observation of the impact of climatic conditions on a fermented or frozen product, for example, demonstrates very well that the effect on a product of a rise or fall in temperature cannot be reproduced if an analysis of the other criteria is not carried out. It is by adding inputs, such as the recipe of the finished product and the impact of raw materials, the workflow and the transit times of the products, as well as the aeraulics, that you see the full extent of how difficult the exercise can be…

FOCUS ON THE FERMENTATION STAGE

FERMENTATION ROOM ENVIRONMENT :

THE PROOFER’S CONDITIONS ROOM AIMS TO

ensure the ideal conditions for the fermentation of products.

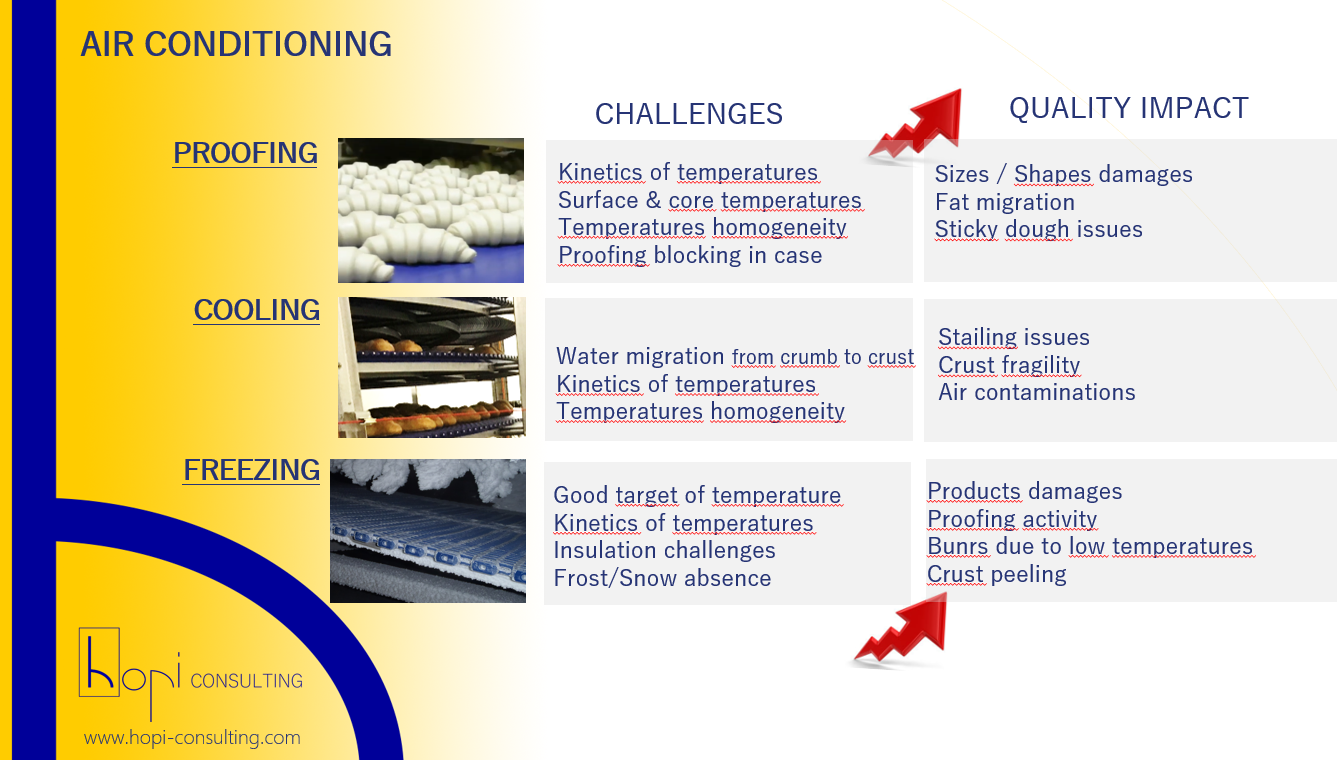

THE CHALLENGES AT THIS STAGE:

- The kinetics involved in the rise in temperature of products is crucial. It is not just a question of defining a target growth temperature, but of reaching it as soon as possible. The impact of this useful time for the product to reach its target temperature within a given time is essential in terms of quality.

- In addition to these rises in temperature kinetics, it is also possible to the block fermentation when it is deemed sufficient by lowering the temperature of the product to stabilise it. And today, this option of total cold blocking is used in the event that the industrial line shuts down in order to limit product losses.

- Control of air humidity and blowing speeds to avoid any drying out of the product surface. On the other hand, do not over do it and cause problems with products sticking to the supports or conveyor belt.

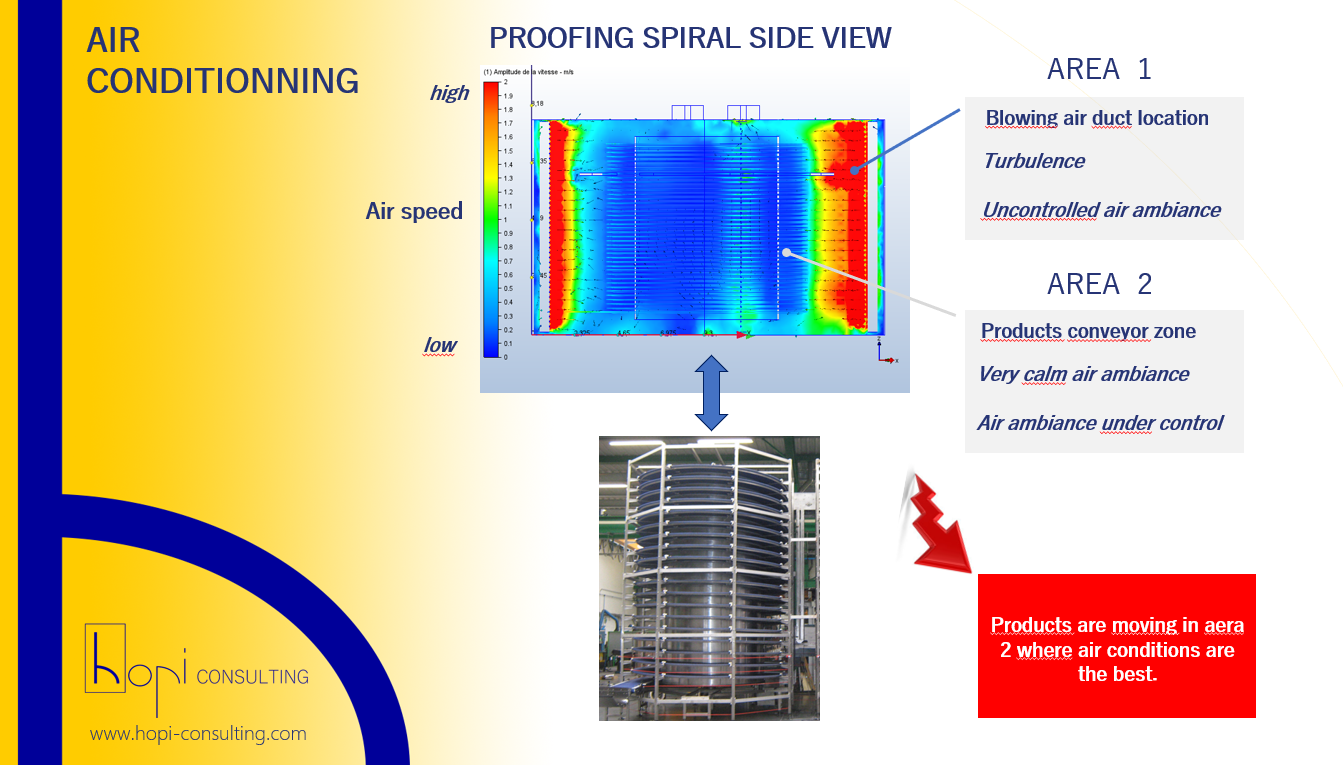

- Secure the risk that the climatic conditions in the environment are heterogeneous by removing all preferential air paths causing different climatic conditions in several spaces within the oven space. This optimum homogeneity of the environment is achieved by means of a sufficient air change rate in the chamber. It is expressed in volume per hour and corresponds to the number of times the volume of the chamber is recycled with fresh air over the course of an hour. A high air change rate is a first guarantee of good homogeneity. The air blowing and return devices must be carefully positioned and adjusted to generate good convection around the products: neither too strong (source of turbulence) nor too weak (source of dead zones). We will see later in this article that the homogeneity of temperature, humidity and air velocity can be described using environmental maps.

MANAGEMENT SOLUTIONS :

CONTROL THE VARIATION OF AIR TEMPERATURE AND PRODUCT:

Today, we must limit the deviation of air temperature in the chamber from the target temperature: this is astability objective. In other words, throughout the fermentation process and at any point in the production range (start-up, mid-production, etc.), the growth temperature must never deviate by more or less than 0.5°C from the target. It is a first performance barrier that must be imposed. This stability criterion can be controlled and described by climate control (it is the difference between the setpoint and the actual measured value).

CONTROLLING VARIATIONS IN AIR HUMIDITY:

Similarly, it is necessary to be rigorous in order to limit the deviation of humidity in the environment. Growth humidity should never deviate from the target by more or less than 3%. It is another performance barrier that must be imposed. This humidity adjustment criterionis achieved by means of cold batteries grafted onto the oven’s ventilation system and by incorporating steam into the air.

CHECK AIR VELOCITY AND AIR CHANGE RATES:

This is achieved by controlling the air change rates, i.e. the ratio of room air in the growth space that is replaced by fresh outside air. This air change rate should be in the order of 20 to 40 volumes/hour.

In addition, the air velocities on the products are neither too high nor too low. Air velocity ranges between 0.3 and 0.5 metres/seconds must beimposed.

ASSURANCE OF ROBUST EQUIPMENT IN GOOD WORKING CONDITION:

This advice is not to be taken lightly. Due to the risks of abrasion and corrosion caused by baked goods and pastry products, the wear and tear of the elements in contact with the proofing air is accelerated and poses a real problem. It is therefore necessary to select resistant equipment, make appropriate choices of materials (with a preference for stainless steel) and design to adapt to air laden with flour, humidity and acid particles.

DIGITAL SIMULATION TOOLS HELP TO ADAPT VENTILATION SYSTEMS TO OVEN CONFIGURATIONS.

FOCUS ON THE COOLING STAGE AFTER THE OVEN STEP.

COOLING ROOM ENVIRONMENT :

Goal is to ensure products are cooled after they have been baked, without hazard of extra drying or contaminations.

CHALLENGES OF THIS STAGE :

As you will have understood by now, many of the issues mentioned above will be seen again in the image of the kinetic control of variations in temperature: do not cool down either too quickly or too slowly. But you must also ensure that there are no preferred cooling airflows that would exclude certain areas in the penetrant test circuit (PT circuit).

However, the post-baking stage has some distinctive features.

For bread products, and more particularly, for “crusty” products such as baguettes, cooling is a risky  business. Basically, if moisture migration from the breads is poor, it results in a crust which loses its crispness and crumbs that are no longer preserved as desired. It is therefore essential to respect the key points in the management of the penetrant testing environment and not to neglect the effect of this step on the quality of the finished product. Hygrometry checks make it possible to closely manage the differences in partial pressure of water vapour between the atmosphere and the surface of the bread crusts, thereby controlling the phenomenon of product evaporation.

business. Basically, if moisture migration from the breads is poor, it results in a crust which loses its crispness and crumbs that are no longer preserved as desired. It is therefore essential to respect the key points in the management of the penetrant testing environment and not to neglect the effect of this step on the quality of the finished product. Hygrometry checks make it possible to closely manage the differences in partial pressure of water vapour between the atmosphere and the surface of the bread crusts, thereby controlling the phenomenon of product evaporation.

Energy saving ideas & FREE COOLING solutions:

The operating principle of the penetrant testing stage is based on the objective of reducing the temperature of the products when they leave the oven, on average from 80°C to 45°C. It is therefore essential to act using 2 combined ways: to extract the heated air from the calories of the cooked products and to replace it with new air that has been cooled beforehand.

The operating principle of the penetrant testing stage is based on the objective of reducing the temperature of the products when they leave the oven, on average from 80°C to 45°C. It is therefore essential to act using 2 combined ways: to extract the heated air from the calories of the cooked products and to replace it with new air that has been cooled beforehand.

The FREE COOLING solution aims to replace the traditional solution of cooling fresh air by passing it through a cold battery of an air handling unit which is itself cooled by glycol water (MPG or MEG). The idea is to replace this energy-intensive heat exchange with a more economical and environmentally friendly solution that uses fresh outside air if conditions allow it. In this case, the fresh air, provided that its temperature is suitable for the desired cooling temperature target, is only filtered and then used to cool the products: this is known as an “all fresh air ” solution or, if mixed with recycled air, as “partial fresh air“.

Control of air hygiene and zero contamination:

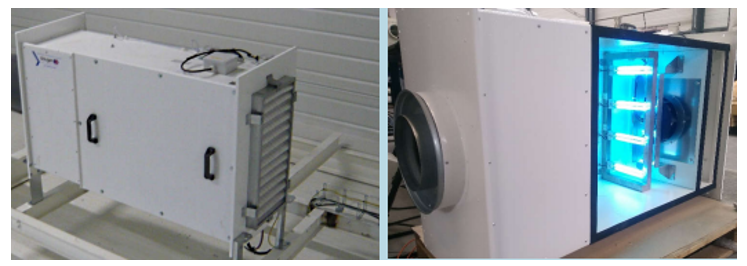

Cooling products remains a risky step in terms of hygiene for all freshly packaged products. This is why filtration techniques and complementary solutions such as treatment with ultraviolet rays offer real guarantees to control the danger of product pollution by contaminated outside air.

The use of high performance filters of the H13/H14 type and ultraviolet lamps make up the range of tools used in penetrant air hygiene.

FOCUS ON THE FREEZING STAGE.

TARGET OF THE FREEZING ENVIRONMENT:

To ensure that the product is frozen while preserving its organoleptic qualities as much as possible.

The challenge of this stage :

Once again, the fundamental points mentioned above must be combined with new concepts specific to deep freezing. Perhaps even more than elsewhere, deep freezing requires the fastest possible deep freezing kinetics in order to preserve the quality of the product. Two examples support this objective. The first is to freeze everything as quickly as possible in order to reduce the amount of water lost from bread or pastries as much as possible. Because this water loss is directly linked to defects in quality such as premature staling of the bread. A second example concerns raw products, the objective being to preserve the fermenting power of products thanks to rapid and efficient freezing. In the case of freezing raw products, the freezing process will usually be conducted in 2 phases: a rapid freezing phase to freeze the products (mechanical holding with a target core temperature of about -12°C to preserve the yeast) and then a slower freezing phase in a cold storage room after packaging.

The deep freezing stage is also a demanding stage in terms of the air treatment process used in BVP. It requires a wide range of technical equipment specific to the creation ofa process environment generally close to a temperature of between -25°C and -30°C. The constraints are very strong to ensure these conditions: very important ventilation of the chamber (the rate of mixing reaches 600 to 800 volumes per hour), thermal insulation of the chamber with the outside (to avoid thermal bridges), thermal exchanges with the refrigeration circuit, etc. Keeping control over the entire freezing system is therefore not easy.

There are new constraints caused by these very low temperatures: those linked to frost in particular. The origin of this pollution for the mechanics of the deep freezer, for the efficiency of heat exchanges and also for the finished product, it originates from the humidity of the latter which, when released into the air of the deep freezer, appears in the form of snow. Here again, consideration of airflow in the deep freezer is essential, as the effects of air balance for example are known to seriously disrupt deep freezing efficiency and lead to frosting.

A strategic financial issue

Energy costs are a key factor in assessing refrigeration systems’ level of performance. The potential energy savings, and therefore electricity bills, are often overlooked as cooling is often set to its maximum in order to ensure a sufficient cooling supply for the process.

Two areas of financial gain are worth mentioning:

- The use of slightly higher evaporation temperatures. For example, using a fluid at -39°C instead of -40°C leads to a saving in consumption of around 5% without necessarily having an impact on the process.

- Similarly, ventilation potential can be optimised: a reduction from 50Hz to 45Hz, for example, can lead to savings of up to 10% in motor power consumption, also without any potential impact on the control of the process targets.

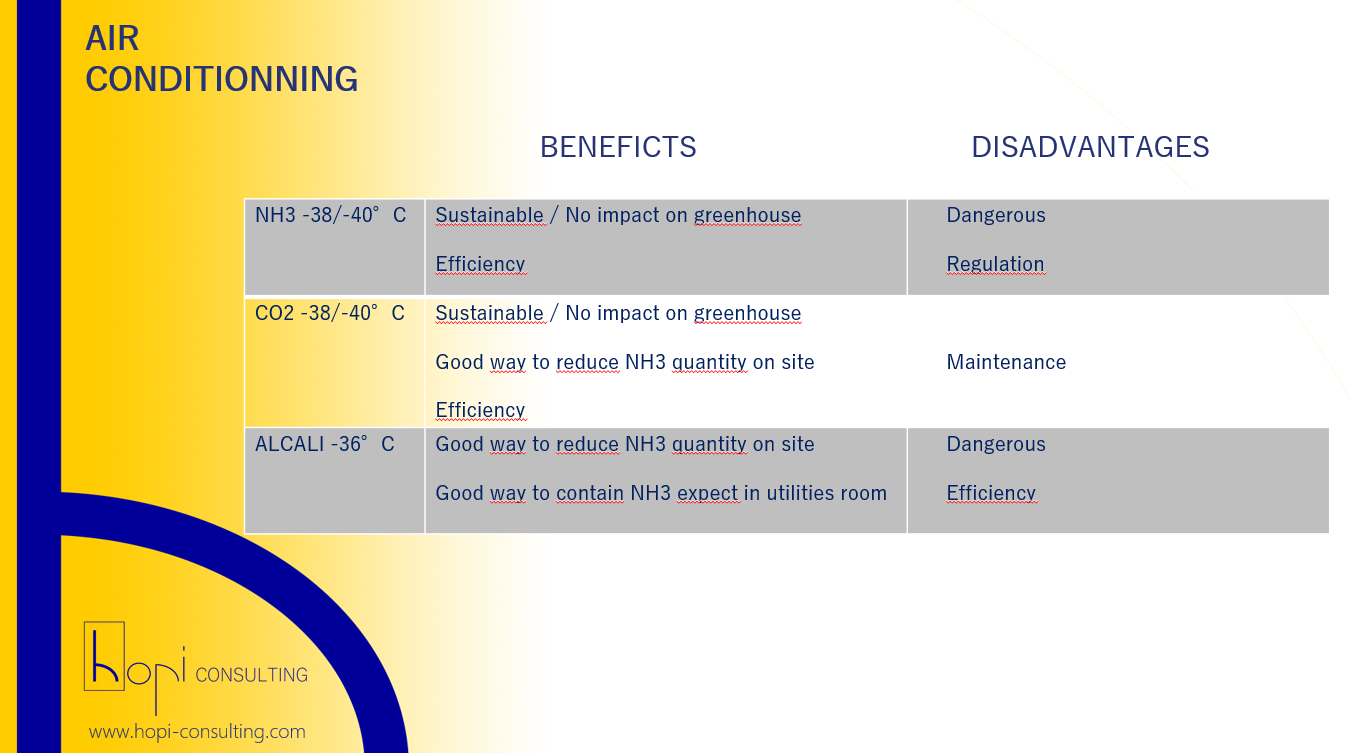

WHICH COOLANT SHOULD I USE FOR MY DEEP FREEZING SYSTEM?

CLAUGER COMPANY PRESENTATION

Clauger is a family business, specialising in industrial refrigeration and air treatment. It currently has 1300 employees and a turnover of €250 million. Its headquarters are in Brignais near Lyon.

What sets the company apart is its distinctive nature in ensuring, for almost 50 years, the design, manufacture, installation, service & maintenance of its installations in France and worldwide.

Indeed, CLAUGER exports its know-how to more than 90 countries and generates 46% of its turnover abroad.

CLAUGER highlights 3 of the company’s key markers:

- Men:

Since its creation in 1971, CLAUGER has always remained a human-scale company. CLAUGER attaches great importance to the development of its teams. The company encourages and supports personal initiatives, trains its employees, etc.

- Innovation

CLAUGER is committed to helping its clients make a difference. Listening to their needs, CLAUGER innovates and offers new alternatives to manufacturers.

- Customer satisfaction

CLAUGER works with more than 3,000 clients – large groups or SMEs – and establishes a long-term partnership, focused on the customer’s requirements.

TO CONCLUDE,

The aim of this article was to provide technical clarifications on the treatment of process environments using BVP, in particular during the fermentation, post-cooking penetrant and deep freezing stages. This subject was particularly close to my heart because of the difficulties faced by many manufacturers. Empiricism, conflicting technical opinions, effectiveness of highly questionable solutions…. I am sure that many players in the BVP world can relate to these words. And yet today, the approach and methods of analysis have developed. The technical solutions used to control climatic conditions are rich nowadays, well adapted to BVP products, and I find them effective.

It was interesting to involve the CLAUGER company which, among others, offers installations such as those presented in this article. Their insight into all these areas of temperature, humidity and air velocity control deserves to be highlighted to you, the reader.

Do not hesitate to discuss these topics with your contacts who are manufacturers of fermentation equipment, deep freezers, etc., and also with your refrigeration partners. They will be able to guide you towards greater serenity and optimisation.

This article was written by Ronan Le Bourhis, Founder of Hopi consulting engineering dedicated to the Bakery, Pastry and Confectionery industries. Discover more articles on hopi consulting blog dedicated to BVP