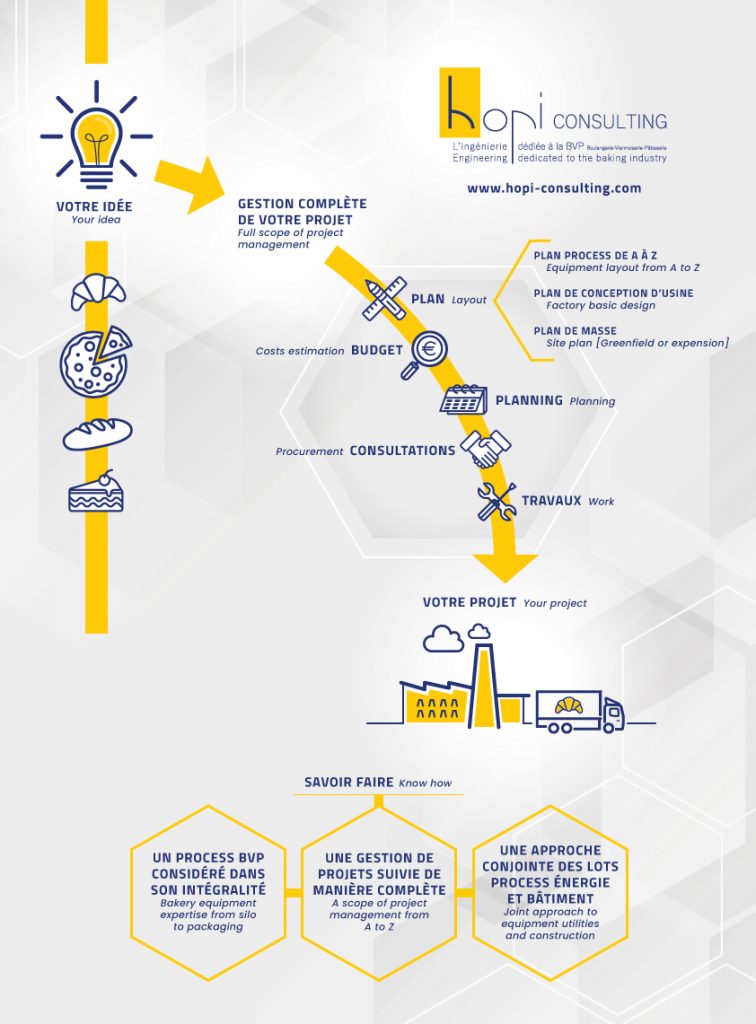

Introduction

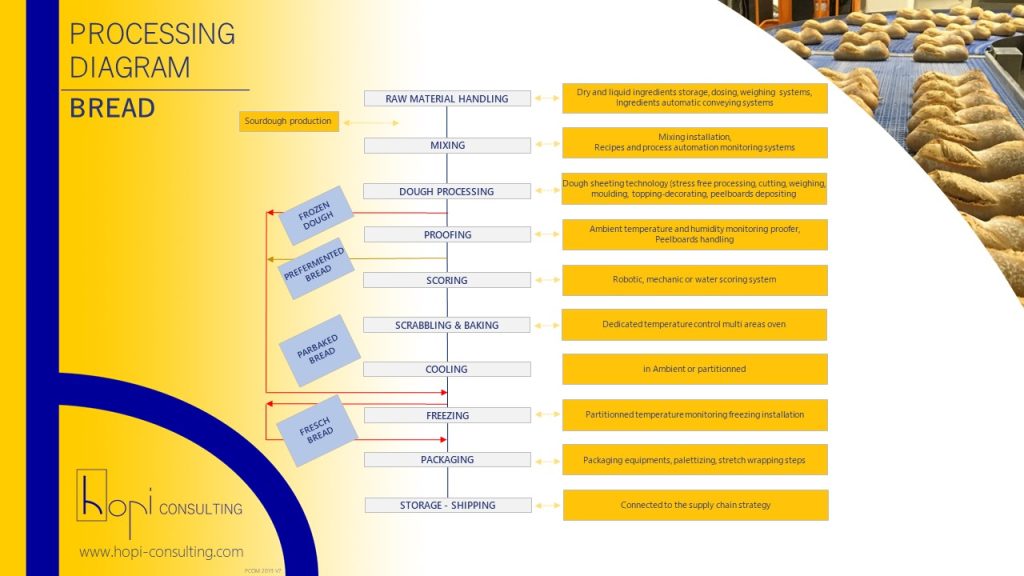

Are you looking for a clear and understandable description about how bread is produced in industry ? Here is a step-by-step description of the bakery industry manufacturing process, enabling large-scale and continuous production of various bakery products such as artisan bread, white bread, ciabatta, buns, brioches, sandwich bread, soft products like milk bread, oriental bread, pizza dough, and rusks.

This article covers the whole production process: from the storage and dosing of the raw materials, to kneading, division and molding, rolling, shaping, proofing, scoring, baking, cooling, freezing, packaging steps and at the end shipment.

To make this article easy to understand we have intentionally decided to omit some technical details which are dedicated to specific bakery products. For instance, rusks require two baking stages. Dough pieces are sometimes sold raw, while other products are partially baked (“part-baked”) or fully baked. Storage conditions also vary based on sales requirements: fresh or frozen.

Let’s highlight a general bakery production diagram without keeping in mind the endless list of all possible production options to make bread.

PRODUCTION STEP BY STEP DESCRIPTION

1 - Storage and dosing of ingredients

This is the first step of the manufacturing process. The goal is to store the ingredients (flour, salt, improvers, yeast, seeds, sourdough…) inside the factory. Dry or liquid, raw materials may be stored with different methods. Palettized bags or small liquid containers stored on pallets arrive in trucks. When quantities start to be important, the best practice is to deal with bulk deliveries. That is to say that major dry raw materials (such as flour, sugar or salt) and liquids (yeast or sourdough) are delivered by tankers and then stored in silos or tanks. If you want to know more about this topic, have a look at pallets racking solutions in the baking industry.

Then raw materials are transfered to the mixing area in order to be precisly dosed according to the recipe. This transfer and dosing stage may be automatic thanks to pneumatic conveying solutions and automatic weighing hoppers.

2 - Kneading

Many bakers will tell you that this is the key step in bakery ! Indeed, this step is far from just mixing ingredients. The kneading stage in breadmaking plays a crucial technological role in the texture of the dough and in the development of flavors and aromas. Installations are often automated and of substantial size, but the functional principle remains very similar to traditional kneading. In a target of quality, a step of dough resting time may be added to upgrade quality, taste and dough texture.

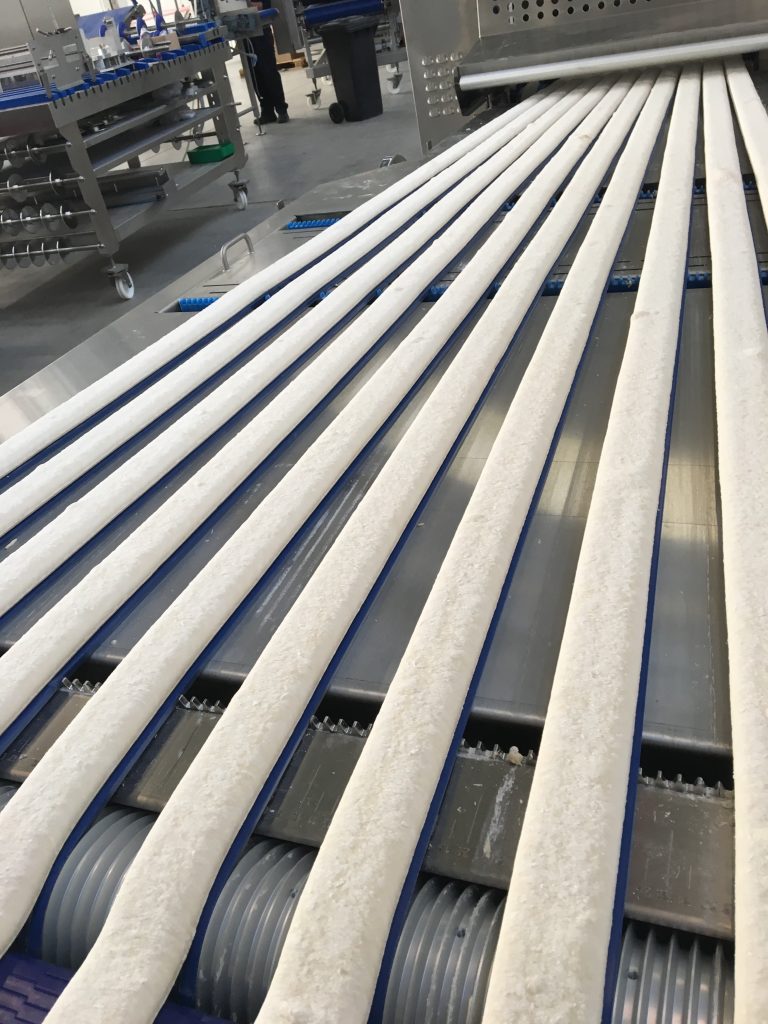

3 - Make-up line

The dough is then conveyed to an industrial production line whose goal is to transform a mass of dough into a nice and almost finished product with the right size, weight, and shape. The make-up line may include at its end fillings and toppings units to fill and decorate the products. These long lines (up to 40 meters), composed of conveyor belts include specialized tools to transform a mass of dough into rows of baguettes, rolls, pizza pieces, buns… And loaves falling into molds in case of sandwich bread or brioche.

There are the two main methods to produce bread in industry: either to divide the mass of dough in loaves at the right final target weight and then carry out the final operations. Or to produce a continuous flow of dough and then carry out the final operations thanks to a lamination process.

4 - Proofing

This “historic” stage allows wheat flour bakery products to gain volume and flavors. Yeast and, optionally, sourdough added during kneading release fermentative gases that are retained by the gluten network in the dough, allowing it to rise. The industrial proofing cabinet is a continuous tunnel through which the loaves rest, and the duration and conditions of temperature and humidity are precisely under controlled to ensure the regularity and quality of the finished products.

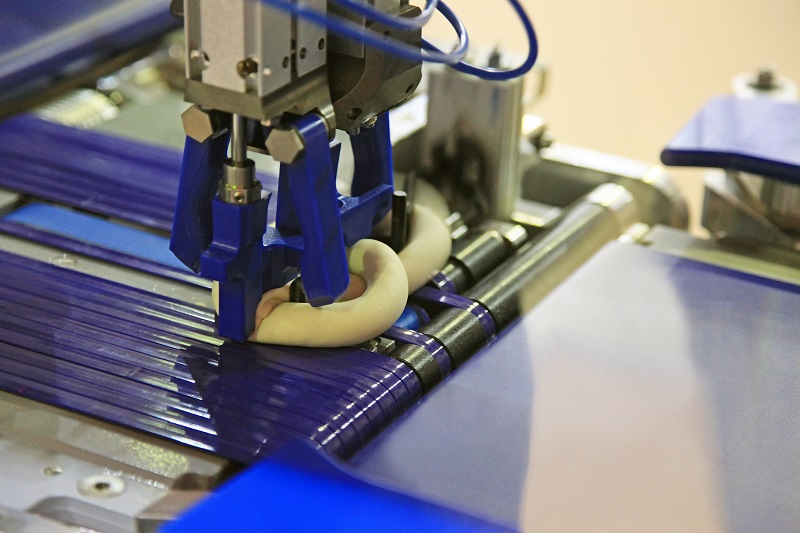

5 - Scoring

A portion of the surface of the loaves is incised to allow the product to expand harmoniously and aesthetically during baking. This industrial step is automated using automated machines or robots replicating the baker’s blade stroke. Different technologies may be used today in industry as well as mechanical, water jet or ultrasonic solutions.

6 - Baking

This is where the delicious aroma of bakery products emerges! At this stage, thermal effects and fermentative processes give the product its final volume. Industrial ovens are tunnels ovens or rotative racks ovens. Once again, parameters such as time, temperatures, humidity (steam), and heat transfer methods are precisely controlled for optimal quality and perfect consistency of production.

7 - Cooling

This cooling step allows the baked bread to cool. It is essential that the products cool down before freezing or packaging, otherwise the risk of degrading the final product’s quality would be very high. The products are stored or even better conveyed in an environment where temperature and humidity are under control to absorb the heat from the products and lower their temperature.

8 - Freezing

For some preservation solutions, finished products are frozen at temperatures close to -25°C in the heart of the loave. The products go in a refrigerated chamber, the time is judiciously calculated to freeze them while preserving their taste and organoleptic qualities. Products can be either conveyed on a belt in a continuous spiral or stored inside a static raks. In both cases, frozen air is blown to reach the target of cold temperature.

9 - Packaging

This stage aims to place one or many finished product(s) in a bag, box or pack. All solutions are possible: several products in cardboard boxes, a single product packaged in a plastic film bag… and consequently, many technical solutions are available based also on the temperature of the product (ambient or frozen). Different stages exist in packaging: the preliminary packaging will be in contact with the loave, the secondary packaging is composed of the carton box which contains the plastic bags, and the third packaging consists in palettizing the carton boxes. Many options may be used during this stage : automated or robotic form and fill installations, automatic packaging machines, use of MAP (modified atmosphere packaging) … diversity is the key!

10 - Storage and shipping

This is the final step. The majority of packaged products are stored on pallets in racks in ambient, cold or frozen warehouses. This stage is a key step in terms of parcel traceability and logistical data; labeling and product flow management are crucial to perfectly control this aspect of the supply chain. Depending on supply requirements, products may be stored for variable duration (from a few days to several months). The shipping dock marks the end of the industrial manufacturing process for the product.

This article is written by Hopi consulting “engineering dedicated to Baking industry“.

Find more technical articles on Hopi Blog.