If you want to know more about PATTYN and discover their offer in detail, this article is for you !

I’ve often been told, and rightly, so, that I haven’t devoted enough of my blog to the subject of packaging. It’s true that the consideration of this important phase at the end of the production line is often neglected, due to budget constraints or a lack of available space. And yet nobody would deny that packaging is one of the major areas of innovation in the bakery industry. Nowadays, the packaging process is enhanced thanks to automated production lines, reduced need for manual labor, faster production speed and reduced waste.

Moreover, packaging should be considered at least as important as the fabrication process : if there is an area where innovation, research and development, and marketing can excel, it’s undoubtly in the packaging phase !

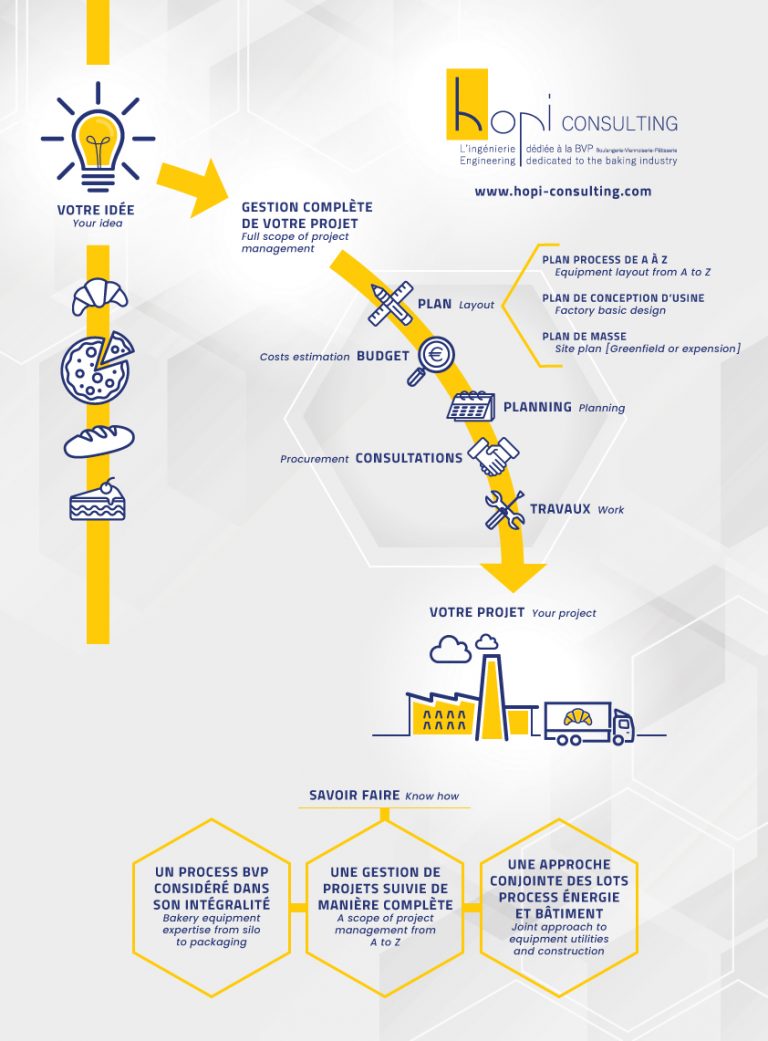

I am Ronan Le Bourhis, founder of Hopi Consulting. I have created these articles with the wish to promote the suppliers with whom I like to share projects, while always keeping in mind my will of independence and impartiality. Discover through Hopi consulting website innovative technical and project engineering solutions, built with a desire for tailor-made solutions and spirit of 100% pure industrial bakery expertise.

First of all, thanks to Arnaud MICHAUD and Philippe VALLOUY for their help in writing this article.

PATTYN.. in a few words

PATTYN FRANCE belongs to PATTYN group, based in Bruges, Belgium. It was born from the merger in 2010 of the French company DE LA BALLINA and the PATTYN branch dedicated to packaging answers, particularly « bag in box » solutions. And recently in 2022 the acquisition of the company VISIO NERF expert in vision dedicated to robotic applications. PATTYN FRANCE was ready to offer expertise in the management of the products flows, as the flow of cases in automated or robotic environments.

PATTYN FRANCE is able to offer a “global and turn-key” offer for end of industrial bakery lines from the exit of production line to the wrapping of the pallet.

PATTYN group in details :

- 450 employees

- A turnover of more than 80 M€ half of which realised in bakery

- 500 packaging lines in bakery

- Lines are running on the 5 continents / more than 1000 customers accros the globe

- 30 years of experience

- Expertise in bakery products but a very wide field of applications: fish, powders, tobacco, corks & food capsules, liquids…

4 production sites :

- PATTYN Belgium Cases and general industry circuit

- PATTYN France Assembly and FAT of complete BVI lines

- GMP Sabadell (Spain) Plastic film production

- PMC PATTYN Metal Construction : Production of frames common to the machine range

Commercial and technical division in the United States, South America, Germany Australia and Asia.

Focus on PATTYN scope of supply

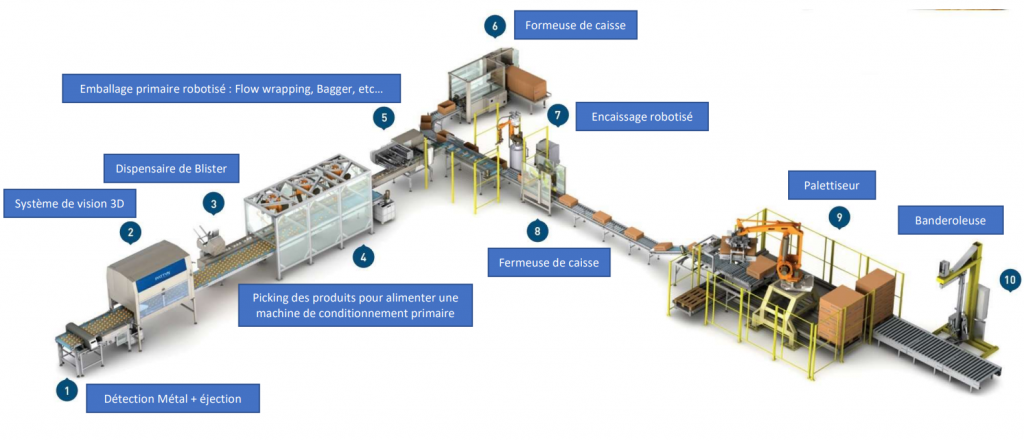

The equipments offered by PATTYN group make it possible to offer automated solutions :

- From the end of production line (right out of the freezer or the cooling step)

- Up to the entrance of the final products warehouse

The scope of supply is very wide and composed of many options :

- Control (DDM, vision, RX…)

- Counting and batch making

- Case packing or bagging solution

- Robotic solution for loading primary and/or secondary packaging

- Range of palettizers adapted to the constraints of the BVI

- Integration of specific solutions on request (marking, labeling, wrapping, …)

- Connection with computerized data systems (ERP, MES, WMS, …)

Expertise in product flow management

Complete packaging solutions for bread-making and viennese pastries

The first stage of PATTYN‘s technical scope starts with the recovery of the flow of finished products from upstream: a freezer or a cooling spiral in most cases. Then, it is thanks to the 3D vision that the stage of conformity control then counting of the products in continuous flow will take place. This 3D vision makes it possible to process products of all sizes and shapes and to operate :

- Quality control, and ejection of non-compliant products

- High-speed counting, and batch separation to prepare for case packing or bagging

- A Pick and place robot control for the specific storage of certain products

FOCUS ON THE IMPLEMENTATION OF QUALITY CONTROL

The 3D vision step is a complete scanning step of each product, all without exception. A complete control of the shape, color, dimensions… is done. A comparison is made with the standards controled by the software in database. If the control is compliant, the product goes on its way to the the packaging. If a difference is lifted between the control and the standard, the product is automatically removed from the flow and rejected.

Here is a link to find out more about PATTYN 3D vision.

FOCUS ON COUNTING AND SEPARATION OF BATCHES AT HIGH RATES

Once the flow of products has been « purified » of non-compliant products, the counting stage can start. It is still the vision that will make it possible to isolate and count each product in continuous flow. The challenge is twofold : count the products but also create the batches of products that will form the right quantities of products in each box/case or each bag.

Here is a link to learn more about the PATTYN counting system.

ZOOM ON PACKAGING PRODUCTS IN THEIR CONTAINERS

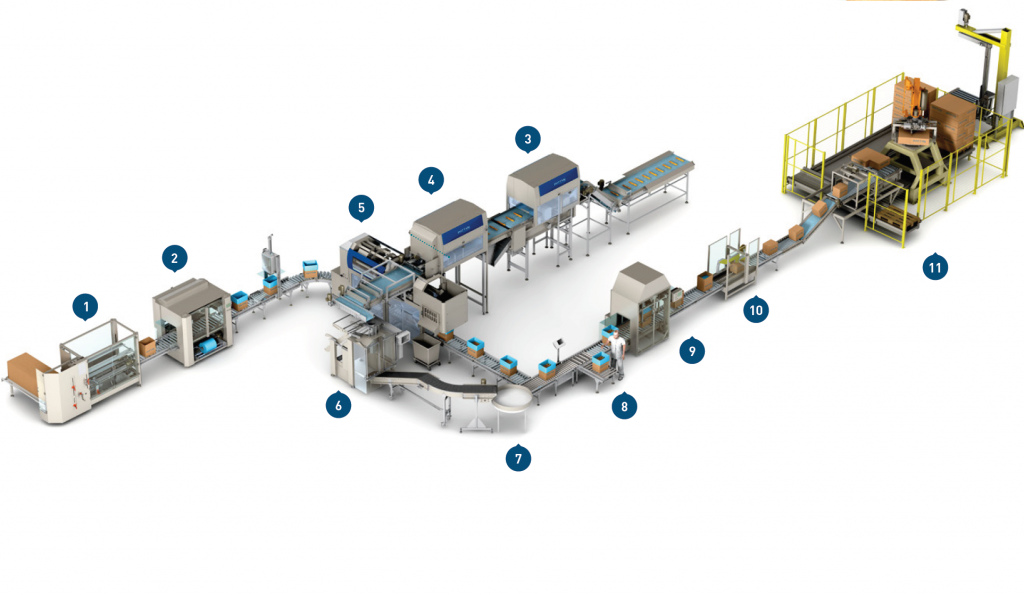

This final part of the production line is where the quality-controlled, finished products, are grouped and placed into boxes or bags. The firm PATTYN offers packaging solutions in two categories : mechanically automated and robotic. In the case of mechanically automated packaging, the products flow directly into the containers. Whereas in robotic packaging, robots mimic human movements, in order to place the products in the containers.

AUTOMATIC BOX FILLER MODULE

In a number of cases, robotic solutions are not necessary. PATTYN then manages a continuous flow of products on one hand and a flow of cases on the other hand to bring them together in a packing station.

AUTOMATIC BAGGING & CASE PACKING MODULE

Positioned behind an Argocount 31 vision system, this module allows the production of closed product bags. This solution can be combined with the automatic case packer Odyssey.

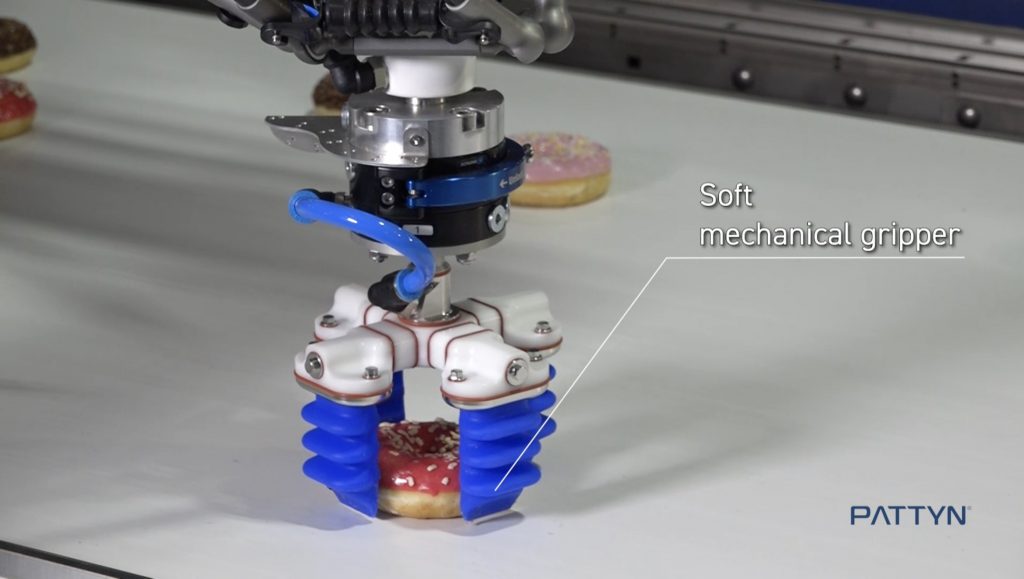

ROBOTIC PACKING MODULE

In certain cases, only the robotic solution can effectively place the products in the containers.

- Some bulky products need to be boxed in a specific way. If these products are left loose, they can become jammed, or the correct number of products may not fit in a case. A good example of this is large partbaked loaves.

- Sometimes fragile products must be boxed precisely to avoid being damaged. Examples of this type of product are donuts or other pastries such as tarts or pies.

- Certain unique packaging formats might necessitate a robotic solution. Sometimes steps such as the mixing of products or the placement of a separator sheet might also be best completed by a robotic solutioon.

PACKAGING BOXES MACHINES

All of these machines are part of a complete production line. In some cases, the handle either the arrival of boxes ready to be filled, or in other cases they deliver packed boxes ready to be closed, placed on pallets and stored.

- Ceflex 41 – Combined Case erector & Bag inserter

- Flexim 41 – Bagmaker Inserter

- CC 31 – Case closer

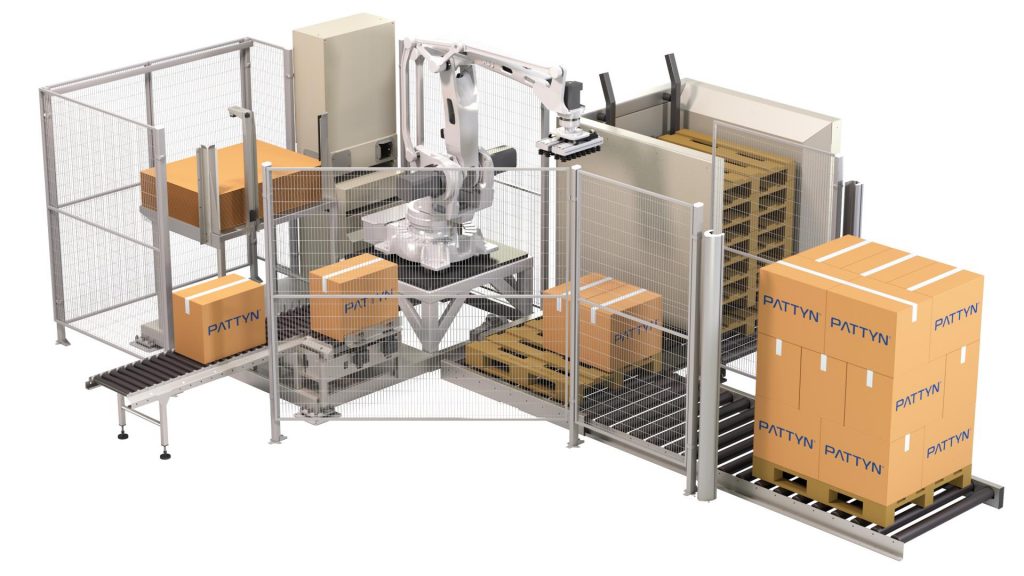

FOCUS ON PALLETIZATION OFFER

PATTYN also proposes complete automatic palletizing and wrapping solutions.

Depending on the need, PATTYN is able to supply common palletization for several production lines. In this case the solution uses a single robot capable of mounting different product references on pallets at the same time.

PATTYN knows how to adapt to the environments and spatial constraints of the building by seeking the most optimized layout.

More information on PATTYN palletizers.

TECHNICAL INNOVATIONS

“Pick and Place” robotic solution for fragile products

The trends in the packaging of baking products are constantly changing, in particular for small products. Some examples are the demand for new types of packaging, mixtures of different flavors, or the arrangement of products in a container… PATTYN has adapted to these changing demands by developing tailor-made robotic solutions, with the know-how to handle delicate products, at high speed and with maximum flexibility.

In details :

The Argo Track 3D monitoring system offers a double solution : the ability not only to count products, but to carry out quality control of each product. This system will only allow products with defined specifications to be packaged.

This double-tracking solution uses delta robots that are capable of handling 4.000 products/hour ! And in a configuration with 4 of these robots, PATTYN can offer packaging at a rythm of up to 16.000 products/hour !

PATTYN offers comprehensive solutions to products packaged on trays in shrink film. For this type of product, PATTYN’s line of equipment can manage the creation of cardboard trays, the use of horizontal bagging machines (with L-shaped plastic heat sealers), shrink film heating tunnels, and the automatic placement of trays at the end of the production line.

This automatic packaging line works with all types of plastic crates, blister packaging or corrugated boxes. The robotic solution can also be combined with the use of a flow pack system for the primary packaging of products in plastic film.

MEC 12 : Bulk box filler for fragile products

One of the latest innovations from PATTYN is the MEC-12 bulk box filler station, that combines the simplicity of loose product packaging with the dilicate handling of products.

The MEC-12 system has been specially designed to preserve the quality of delicate products such as seed burns, or other fragile products.

The system has two flexible doors coated in polyurethane, and a box elevator, allowing the boxes to be raised to the necessary height so that the products will fall no more than 300mm, guaranteeing gentle handling of the product.

There are three modes of operation:

- Fragile products : 8 to 10 boxes/min (double deposit)

- Fragile products : 12 boxes/min (simple deposit)

- Non-fragile products : 20 boxes/min

A winning combination : MEC 12 + Argocount 31

This PATTYN bulk box filler works ideally with the Argocount-31 vision counting system. The Argocount-31 placed before the packaging system in the production line will ensure optimal performance.

Latest machine for managing the flow of boxes PATTYN Ceflex 41

The Ceflex 41 is the fourth generation of machine combining box making and filling. It can be ordered to use glue or tape, and can adapt to all types of corrugated boxes.

- Placement of bags delivered from a plastic roll of 12 to 60Kg

- Automatic spool change

- Excellent autonomy

- Small footprint

- Perfect alignment of boxes with adhesive tape as Hotmelt

- Up to 12 boxes/min

TO CONCLUDE,

And to conclude, a company is only as good as the men and women who work there. From the technical expertise to the culture of tailor-made solutions, I’ve always enjoyed working with the team at PATTYN. It’s with joy and confidence that I begin new projects by their side !

If you would like to find out more, take the time to visit PATTYN website.

This article was written by Ronan Le Bouhris, founder of Hopi Consulting, the engineering firm dedicated to the Bakery, Viennoiserie and Pastry industry. Discover more articles on the Hopi Consulting Blog dedicated to BVP.

Discover our innovative formula to bring assistance to your project in the bakery industry ! Let’s get in touch !

And thanks to Valentin KEREBEL for his participation to the creation of this article.

This article was translated from French to English by Phillip Meade. Phillip offers translation services and English language training. He can be contacted at phillipmeade@gmail.com / 06.58.77.38.57