If you want to know more about RONDO company, this article is for you!

One more article dealing with a visit to a supplier ! I thought very interesting to focus on RONDO because I had the feeling that my opinion was wrong about this company. And I was right ! RONDO has changed and is definitely different from the one we knew past years ago.

To write this article, two visits have been carried out, in Switzerland and in Italy. A good opportunity to meet the teams, to see their facilities and to discover their show rooms. The more I travel, the more I figure out that these onsite visits are the best ways to release technical news.

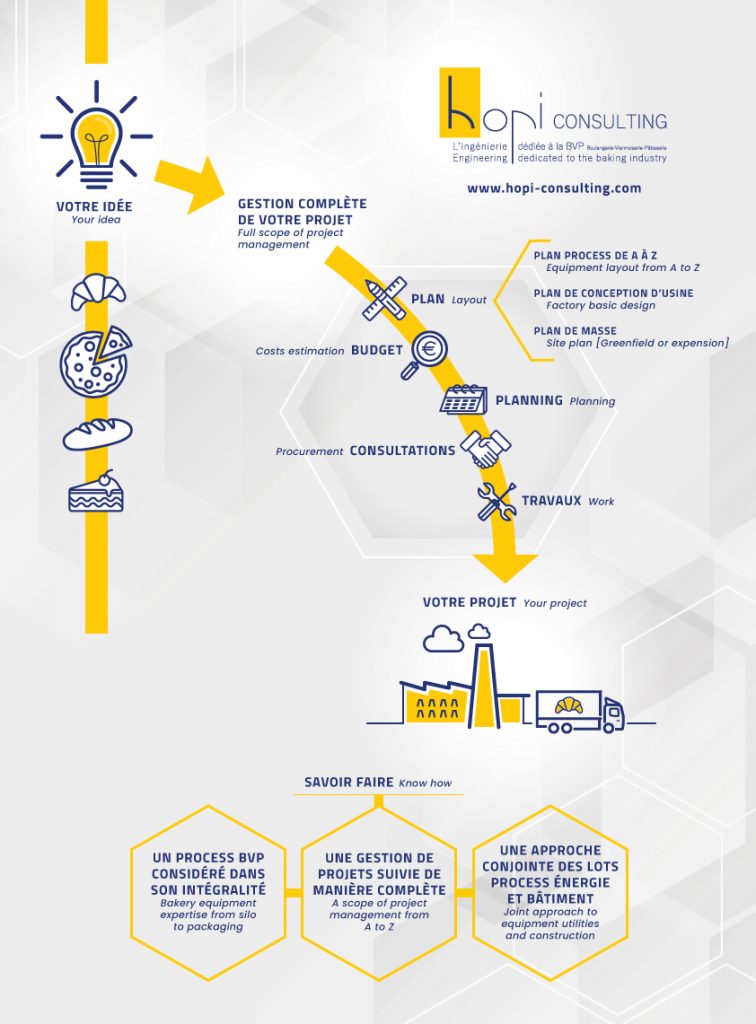

I am Ronan Le Bourhis, the founder of Hopi Consulting. I came up with this blog with the wish to promote the suppliers with whom Hopi Consulting shares projects, by always keeping in mind a crucial point: staying independent and impartial.

Discover our website, new technical support solutions and project management with a guarantee of tailor-made solutions. What about a 100% pure industrial bakery expertise assistance ?

The goal of these articles is to bring a neutral and external point of view of the market. A good way to discover technical solutions from equipment manufactures dedicated to the bakery industry. Our role is to highlight their equipment without any sales promotion. Read this article and enrich your own knowledge. Your comment and critique are probably justified because the baking process is “an art composed of several truths” : everyone can make his own opinion.

First, many thanks to Johnny HECHT and Marc TOUSSAINT for their support in writing this article.

RONDO.. IN FEW WORDS

RONDO will celebrate its 75th anniversary this year. A story started in 1948 when Gustav. A Seewer founded the first workshop in Burgdorf in Switzerland. Today, the company is still fully independent and belongs to the same family.

Key figures :

- 2000 : RONDO purchased DOGE

- 425 employees (110 in Italy / 200 in Switzerland / 50 in France / 30 in USA)

- 11 International agencies all around the world

- 3 Sales offices

- 3 Production centers (in Italy, Switzerland and France)

- 3 Demo centers (in USA, Italy et Switzerland)

RONDO, has split its technical solutions in 2 fields to bring dedicated machinery to :

- Industry : including goals of quality, continuous process and high capacities (up to 1500kg/h – from 600mm to 1500mm belt width)

- Craft bakeries and medium size facilities : based on flexible discontinuous solutions (from 350kg/h up to 800kg/h)

RONDO brings only laminated process solutions especially dedicated to produce :

- Croissant and other viennoiserie products

- Bread

- Pizza

- Donuts

- Pastries

RONDO insists on the fact that their solutions bring major benefits :

- An intuitive online control with symbols and operator aids

- The last generation MIDOS Stress Free extrusion technology

- A continuous croissants machine « CS » offering flexibility and efficiency

- A robotized continuous rounding technology : the RONDObot

- A reliable and robust butter pump, up to 1 tons/h,

- An ASTEC line designed for hygiene challenges and easy cleaning

SPECIFIC FOCUS ON THEIR PRODUCTION SITES

RONDO succeeded to control from A to Z its manufacturing process. That is why we can see during the visit that the assembly of the different parts of a make-up line is just the final step of a very long process. We have seen all kind of preliminary stages : laser cutting, bending, welding… One surprising step is the metal mass cutting for high mechanical solicitations parts : the guarantee of the very high durability and quality over time.

Burgdorf – SWITZERLAND

This site is dedicated to the production of craft bakeries and medium size facilities machinery.

Schio – ITALY

This site produces equipment tailor made for industry.

Wasselonne – FRANCE

This site is dedicated to preliminary steps as well as metal cutting or shaping.

FOCUS ON THE DEMO CENTER

A BRIEF HISTORY OF DOUGH SHEETER

A dough sheeter : what is it for ?

We can compare the dough sheeter to a big rolling pin.

The goal is to crush the dough to reduce its thickness and to extend its length. This operation is carried out for 2 reasons :

-

-

To obtain the right thickness and the right size, this is the case in the pastry industry for pies for example.

-

To introduce butter to the dough and obtain puff dough for viennoiseries for example.

-

1953 : G. A. Seewer patents the first dough sheeter

1983 : Marketing of the first electric dough sheeter

FOCUS ON RONDO TECHNICAL SUPPLY

DOUGH SHEETER AND PRESS

PRODUCTION LINES FOR MEDIUM SIZE INDUSTRIES

MLC 4.0 Block Line is designed for viennoiseries and offers a modular and scalable line. It is possible to create your own line step by step, with successive investments :

- Dough extrusion from the mixer bowl

- Butter introduction

- Continuous laminating process

- Continuous dough sheeting

- Continuous dough cutting

POLYLINE is the first step toward a fully continuous and automated line. It brings a medium level of capacity, is versatile and flexible to produce a wide range of products : bread, viennoiserie, filled products…

Other lines are dedicated to higher level of capacities.

STARLINE is a viennoiserie and filled or topped products production line.

SMART DONUT LINE is an automated production line for donuts but also for other fried bakery products.

THIN DOUGH LINE is an automated line for regional products such as spring rolls, samosas or börek.

PRODUCTION LINES FOR INDUSTRY

ASTec industrial lines have been designed based on targets of high cleanability and hygiene challenges. They bring smart solutions including accessibility, easy dismantling, and reduction of dust areas.

Several variations are available :

- ASTec Bread Line dedicated to bread and small bread

- ASTec Croissant Line dedicated to croissants

- ASTec Pizza Line dedicated to pizzas

- Astec Donut Line dedicated to donuts

- ASTec Pastry Line dedicated to pastries

INNOVATIONS

RONDObot

RONDObot is a robotized continuous rounding tool. The rotation is made thanks to an innovative robot located on the line. This solution brings new perspectives in terms of productivity and innovation.

FUTURE PROJECTS

RONDO looks forward and anticipates coming needs in the baking industry. New automate equipment and lines, deported controls, autonomous intelligence to reduce the workforce onsite are current . Great challenges !

TO CONCLUDE,

The goal of this article was to highlight RONDO firm and to focus on its solutions for the baking industry.

RONDO company has changed a lot for this past decades. It was important to take some time to discover the different fields of solutions, dedicated to the craft bakeries, the medium size industries and bigger industries. And to focus on very nice innovations !

It was a great opportunity to discover a real know-how and to understand how RONDO puts under control its production process from A to Z. The mix of French, Swiss and Italian cultures brings a rich cocktail of human and technical values !

Visit RONDO website and find more information about the company and their technical solutions dedicated to the baking industry.

This article was written by Hopi consulting. Our motto : engineering dedicated to the baking industry ! Discover more articles on the Hopi Consulting Blog dedicated to baking industry.

Hopi Consulting brings new technical support solutions for a complete project management of your industrial project in bakery ! Let’s get in touch to discuss it !