Do you want to know more about VMI company? You may be interested in this article…

I am Ronan Le Bourhis, founder of Hopi consulting. With these articles, I wish to promote suppliers with whom like to share projects, keeping in mind my goal of working with independence and impartiality.

First, many thanks to Mikaël ROUSSIERE and Claire AUFFREDOU for their support in writing this article

VMI COMPANY IN A FEW WORDS

VMI is a French company located on the west coast of France in an area called Vendée. Its history began in the post-war period with a mechanical engineering business. Later in the 60’s, first mixers are sold to the bakers as well as cosmetic and laboratory workshops (at that time manufactured by a company named Rayneri acquired by VMI in 1990). Nowadays, the company is well known as VMI which are the three first letters of the full historical name of the company : Vendée Mécanique Industrie.

VMI has a business activity in France but not only. Thanks to the growth and expansion abroad of its historical French customers from baking industry, VMI is today a major supplier of mixing equipment all around the World. France is still being a key market for the company, VMI offers a scope of specific range of equipment for bakers customers without any matter of dimension : craft baker or industrial one.

In short : VMI has become a key player for mixing equipment for the baking market all over the world. And I am delighted to add : VMI is a 100% French company !

Here are some key figures: VMI employs 230 people and achieves € 55 million revenue, with more than 50% toward export. VMI belongs since 1998 to a French group leader in specialized equipment solutions for food and health industries which decided to strenghten its awarness by becoming LINXIS Group in October 2017.

One key point: VMI controls each step : from design stage to manufacturing and commissioning stages. As a result, VMI company moved recently to huge new 13 000 square meters premises to achieve these commitments. This new building has also a Process Development Center dedicated to R&D bakery trials and equipment qualification steps.

To conclude this introduction I would like to share a more perspective. With all the projects we have carried out together for the baking industry, the last one by the way still in progress, I always feel the same about this company: the wish to share passion for dough and know-how about mixing whenever it is possible.

SCOPE OF SUPPLY

Mixing solutions but not only…

Vertical mixers with removable bowls

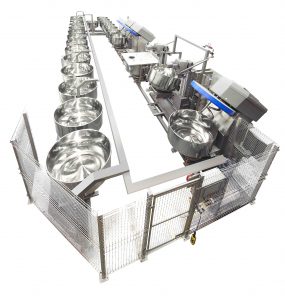

Automated batch systems

Automated batch systems from VMI are the best solution to combine high productivity and quality. A smart shuttle controlled by a PLC manages the bowl transport to ingredients, scrap dough dosing stations, resting  station and at the end to the bowl elevator for dough transfer to the make-up line. The size of the installation, the choice of its mixing tool and the number of bowls are based on the targeted dough capacity and resting time. As a result, there is not limit in the number of recipes and targeted products. This kind of equipment is well adapted to “artisan” products with need for long dough resting time. Once again, VMI offers a large range of options as well as a hanging shuttle system for more hygiene.

station and at the end to the bowl elevator for dough transfer to the make-up line. The size of the installation, the choice of its mixing tool and the number of bowls are based on the targeted dough capacity and resting time. As a result, there is not limit in the number of recipes and targeted products. This kind of equipment is well adapted to “artisan” products with need for long dough resting time. Once again, VMI offers a large range of options as well as a hanging shuttle system for more hygiene.

Continuous mixer

Continuous mixers are the dedicated tools to produce dough with a high  level of energy. This technology is the one for products such as puff pastries, buns or sandwich breads. The range of capacity is large, starting from 500kg/h (11000 lbs) up to 8 000kg/h (18,000 lbs) !

level of energy. This technology is the one for products such as puff pastries, buns or sandwich breads. The range of capacity is large, starting from 500kg/h (11000 lbs) up to 8 000kg/h (18,000 lbs) !

As their name suggest it, continuous mixers produce dough without any interruption, unlike batch mixers which don’t provide dough between two batches. VMI continuous mixing solutions consists of two stages. The first one is a premixing phase(VMI patented technology), to homogenize all ingredients. The  second step is the continuous mixing phase, in a horizontal double-jacketed tank, with glycol in the jacket. The dough gets in the tank from one side, and thanks to a horizontal mixing tool, the dough is mixed and transferred to the other side, to the gate. A conveyor then transfers the continuous flow of dough to the hoper of the make-up line. Of course, scrap dough is reintroduced in the mixer.

second step is the continuous mixing phase, in a horizontal double-jacketed tank, with glycol in the jacket. The dough gets in the tank from one side, and thanks to a horizontal mixing tool, the dough is mixed and transferred to the other side, to the gate. A conveyor then transfers the continuous flow of dough to the hoper of the make-up line. Of course, scrap dough is reintroduced in the mixer.

Planetary mixers

Planetary mixers are perfectly suited for pastries, as well as highly viscous or thick products with high proportions of powders or inclusions. By processing in a controlled atmosphere, under vacuum or pressure, along with heating/cooling and cleaning in place, the range of planetary mixers from VMI offers a great versatility and a very high level of performance.

INNOVATIONS

Let’s focus on innovations by VMI to meet one of the current demand for : artisan breads.

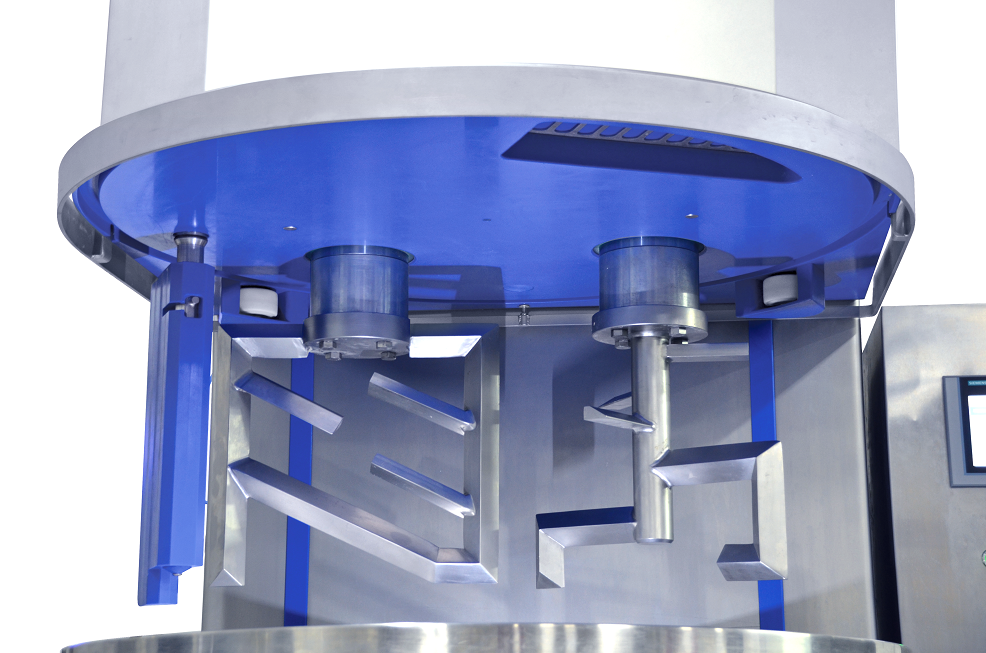

Based on VMI’s innovative technology, the Kneadster mixer is equipped with an exclusive design, double mixing tool. As the tools have a bigger diameter, a specific shape and position in the bowl, they facilitate the insertion of gas aeration in the dough for even more consistent mixing. This allows slower kneading. With less effort to produce, the machine lasts longer and is more reliable.

The Kneadster mixer is declined in a version dedicated to “SNACKING” activities such as pastries, cakes, biscuits but also salty or sweet filling preparations.

The Kneadster mixer is adapted to productions with long fermention stages or with high level of sourdough. It is also smartly suited to produce long shelf life or clean label recipes.

In addition, VMI can integrate its Kneadster mixer in an automated batch system with shuttle transporting sponge or very long time resting dough bowls.

TO CONCLUDE…

VMI has understood that the demand of the market has changed to more and more variety of products with also a demand from the customers for high levels of quality and consistency. That is why the current scope of mixing equipment of VMI offers solutions to produce with productivity, agility and versatility. The ability to change resting times or fermentation times, the way to mix, the level of energy brought into the dough, the level of automation are some examples showing how VMI has adapted its range of equipment for new and dedicated solutions.

In spite of its growth and size today, I really enjoy sharing industrial projects with VMI because it is a French company with a human dimension. I am always at my ease when sharing projects with a team ready to build partnership and share technical knowledge to find tailor made solutions far away from everyday standards of the market.

If you want to know more about VMI company, visit its website.

This article has been written by Ronan Le Bourhis, founder of Hopi consulting, engineering dedicated to the baking industry. Discover more articles in Hopi consulting blog.