TUNNEL OVENS IN THE BAKERY INDUSTRY

FOCUS ON MECATHERM COMPANY

Industrial bread processing diagram is composed of many stages, all of which are strongly important. However, the baking step in the bakery industry remains a key stage. This is the time for the dough to become the final expected product: a piece of bread, viennoiserie or cake for example. In my point of view, bread processing makes sense when the products are coming out of the oven. According to its size, color, shape, smell…the final product is thoroughly studied during and after baking. It is still the best way to judge the quality of the work done.

You will find in this article information about tunnel ovens solutions in the bakery industry. An opportunity to get not simply a large vision of current tunnel ovens technology but also understand the different ways to bake products.

At the end, you will find a focus on MECATHERM company with a description of its scope of tunnel ovens supply and much more…

Many thanks to Marie LAISNE for her technical help and Raymond NOGAEL for his support.

HEAT TRANSFER MODES

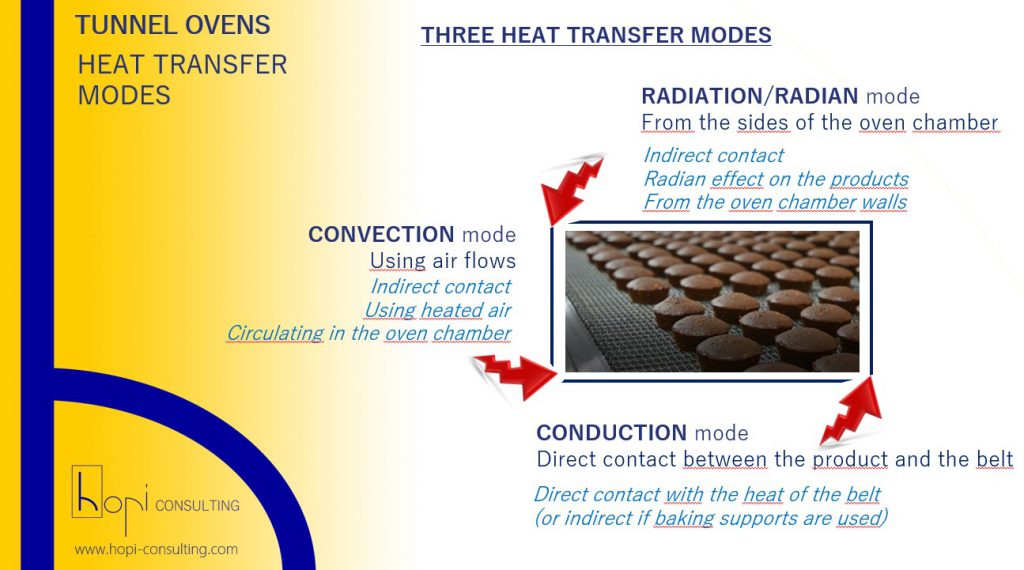

To start, an introduction of the three ways to transfer heat to the product is necessary.

Heat transfer is the physical act of thermal energy being exchanged between two systems by dissipating heat.

Heat transfer can be grouped into three categories: conduction, convection, and radiation.

.

Baking oven technology are being based on that knowledge. Current and successful innovations mix these three heat sources to bring more efficiency and accuracy during baking time. A way to optimize, fine-tun and get dedicated baking parameters for each range of products. Baking time settings become now unlimited and the step in the oven is now divided in different stages with dedicated parameters each time.

HYGROMETRY AS A CRUCIAL POINT

This article about baking in the bakery industry would not have been completed without this zoom on humidity and ways to put it under control.

Hygrometry? Humidity? Steam? To make it simple: air is composed of water in the form of a gas named steam. Humidity is the standard term to name what steam is. Hygrometry is a technical value which corresponds to the percentage of humidity in a saturated air.

Adding steam during baking is very conventional, especially during the first minutes in the oven. Why? to avoid an early dehydration of the dough and maximize its stretchability before fermentation. Steam also optimizes critical color reactions which are so important for many products in the bakery industry.

Adding steam during baking is very conventional, especially during the first minutes in the oven. Why? to avoid an early dehydration of the dough and maximize its stretchability before fermentation. Steam also optimizes critical color reactions which are so important for many products in the bakery industry.

New and current technology have permitted to achieve two main goals: to put under control steam injection in the oven and optimize hygrometry all along baking time. The target is to adjust the settings of humidity in the oven with dedicated settings for each range of products.

ENERGY SOURCES

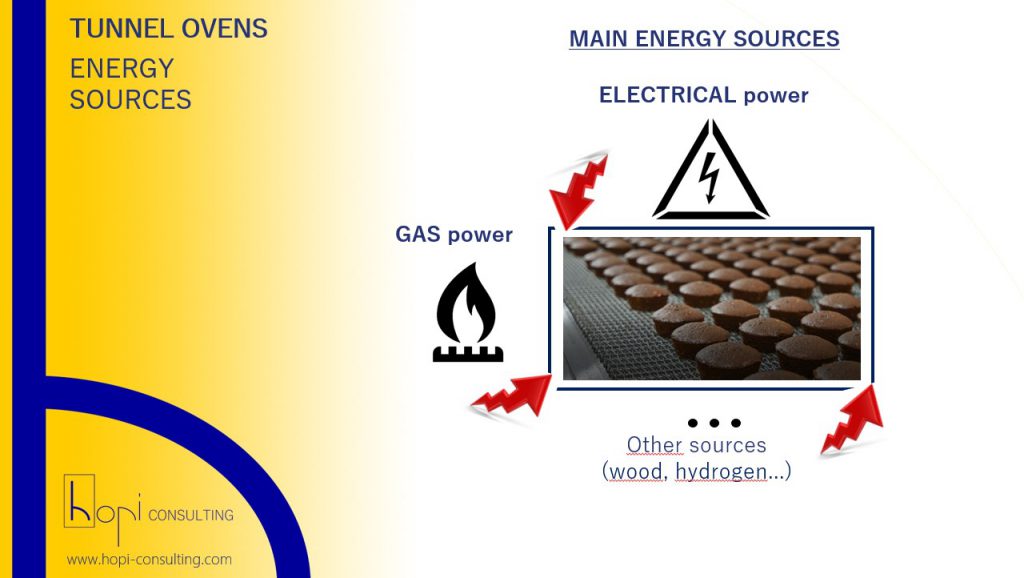

The choice between different energy sources helps also to identify the type of industrial tunnel oven. Whichever will be the choice, electrical power will be required, at least for its fundamental needs (mechanical / automation parts) but different solutions to generate heat are possible.

The choice between different energy sources helps also to identify the type of industrial tunnel oven. Whichever will be the choice, electrical power will be required, at least for its fundamental needs (mechanical / automation parts) but different solutions to generate heat are possible.

Electricity and gas remain the two main energy sources to generate heat in a tunnel oven in the bakery industry. It is true that for some products, gas or electricity are sometime more appropriate. But at the end, choices are based on other factors such as: price and cost of supply, existing energy source already on site, routine, availability and security of supply in both short and long terms.

That is why it is very difficult to conclude so easily by saying electricity or gas is THE best energy source. In fact, each situation requires to be studied to adapt the energy source to all previous factors just listed above.

Electricity:

Electrical ovens take advantage of the Joule effect to generate heat. Thanks to resistances, energy can be used in two different ways. Either heat is directly freed by radiation from electrical resistances located all around the frame of the oven. In another case, heat is produced in a specific area and carried by air flows thanks to a mechanical convection system using electrical resistances connected to electrical fans.

Electrical ovens take advantage of the Joule effect to generate heat. Thanks to resistances, energy can be used in two different ways. Either heat is directly freed by radiation from electrical resistances located all around the frame of the oven. In another case, heat is produced in a specific area and carried by air flows thanks to a mechanical convection system using electrical resistances connected to electrical fans.

Gas:

In any case, gas ovens require electricity, at least for basic needs such as mechanical and automation needs. But heat is produced thanks to fire generated from a gas burner. Then, this flame either directly points into the oven to warm the oven chamber or can be connected to a heat exchanger. In this case, hot air coming from the flam transfers its energy through a heat exchanger to a second air system. Heat is then either blown directly into the oven chamber (convection solution) or carried through resistances located in the frame of the oven (radiation solution).

In any case, gas ovens require electricity, at least for basic needs such as mechanical and automation needs. But heat is produced thanks to fire generated from a gas burner. Then, this flame either directly points into the oven to warm the oven chamber or can be connected to a heat exchanger. In this case, hot air coming from the flam transfers its energy through a heat exchanger to a second air system. Heat is then either blown directly into the oven chamber (convection solution) or carried through resistances located in the frame of the oven (radiation solution).

The flame of the gas burner can also be used in a thermal oil heating system. In that case, heat is not carried through air anymore but in a hot liquid oil ring. Find more information about thermal oil heating system oven technology just below in this article.

What else?

There are other energy sources but examples are more unusual. The reasons? a lake of efficiency for some and a lack of technical necessary distance for others.

Wood fired ovens are tailor made baking solutions for some typical types of breads and pizzas. One or many wood fire areas composed the oven. The heat and the smoke coming from the fire is directed into the oven chamber for a direct contact with the product. But new ovens can also propose a heat exchanger to bake the products thanks to a modern convection system and no direct contact with combustion air.

Wood fired ovens are tailor made baking solutions for some typical types of breads and pizzas. One or many wood fire areas composed the oven. The heat and the smoke coming from the fire is directed into the oven chamber for a direct contact with the product. But new ovens can also propose a heat exchanger to bake the products thanks to a modern convection system and no direct contact with combustion air.

The hydrogen is said to replace natural gas or electricity power tomorrow. An indisputable green choice with a second fundamental benefit, its long-term supply availability. This technology consists in using hydrogen and a fuel cell system operating on hydrogen to provide electricity and so on heat to the oven. A hydrogen oven is in other words an electrical oven able to produce its own power.

The hydrogen is said to replace natural gas or electricity power tomorrow. An indisputable green choice with a second fundamental benefit, its long-term supply availability. This technology consists in using hydrogen and a fuel cell system operating on hydrogen to provide electricity and so on heat to the oven. A hydrogen oven is in other words an electrical oven able to produce its own power.

STONE BELT OR STAINLESS-STEEL METAL BELT?

Here comes a main distinction and choice: what will be the baking surface made of? In other words, on which surface your products required to be baked on?

Stone belt oven:

This is a typical French standard. In that case, the conveying belt is made of firebrick stones. The stone belt makes a round trip in the oven, on one way with the products carried on, then empty on the other way. And so one again and again. The stone surface of the belt is brushed and heated before starting a new cycle. This is a way to maintain a very high temperature of the stones when products are loaded on the belt.

This is a typical French standard. In that case, the conveying belt is made of firebrick stones. The stone belt makes a round trip in the oven, on one way with the products carried on, then empty on the other way. And so one again and again. The stone surface of the belt is brushed and heated before starting a new cycle. This is a way to maintain a very high temperature of the stones when products are loaded on the belt.

What kind of benefits bring a stone belt oven? First, this choice guarantees a very good transfer of heat by conduction thanks to the direct contact of the product on the stone. Then, from a marketing point of view this solution is the only one to sell “products baked on stone”. In my opinion, a stone belt and a metal belt give approximately the same results after baking.

What kind of benefits bring a stone belt oven? First, this choice guarantees a very good transfer of heat by conduction thanks to the direct contact of the product on the stone. Then, from a marketing point of view this solution is the only one to sell “products baked on stone”. In my opinion, a stone belt and a metal belt give approximately the same results after baking.

I can give you an easy way to see the main difference between the two technologies. It takes place under the products: stone baked products are perfectly smooth, metal belt baked products have small belt meshes marks as a proof of the technology used…

Stainless steel metal belt:

This is a much more common choice. Products are conveyed from the infeed of the oven to the outfeed on a metal belt  composed of meshes. The conveying system is the same as the one with a stone belt except the fact that the belt is made of stainless steel meshes and very small holes. The contact surface of the belt and the product is therefore a little bit reduced compared to a stone belt. But this technology brings cost benefits and makes maintenance works easier.

composed of meshes. The conveying system is the same as the one with a stone belt except the fact that the belt is made of stainless steel meshes and very small holes. The contact surface of the belt and the product is therefore a little bit reduced compared to a stone belt. But this technology brings cost benefits and makes maintenance works easier.

BAKING SUPPORS: PANS, TINS, TRAYS AND MOULDS

Some products required to be baked in baking supports such as tins or moulds. That is the case for the buns, cakes, or sandwich breads. It is easy to understand that this tray will act as a barrier to the transfer of heat by conduction. That is why these products requires a very high level of energy to be well baked.

MULTIDECK TUNNEL OVENS

This range of compact ovens can bring serious benefits when space free is an issue. Actually, a multideck oven is a way to keep the same baking capacity with an optimized oven length. Baking surface is divided by the number of levels, as needed up to 2, 3, 4 or more. A system to load the products in the infeed of the oven and unload at the outfeed are required to reach each level. It is possible to bake at the same time, of course not at the same level, different recipes with different baking setups.

This range of compact ovens can bring serious benefits when space free is an issue. Actually, a multideck oven is a way to keep the same baking capacity with an optimized oven length. Baking surface is divided by the number of levels, as needed up to 2, 3, 4 or more. A system to load the products in the infeed of the oven and unload at the outfeed are required to reach each level. It is possible to bake at the same time, of course not at the same level, different recipes with different baking setups.

ENERGY SAVINGS

New ovens can now be configured for maximum energy efficiency. Intelligent control system that communicates continuously with the central heating system is an example. Otherwise, heat recovery systems are in my opinion intrinsically the most economical energy savings solution. The concept is to install a heat exchanger directly into the exhaust gas of the oven. This recovered heat can be used to provide hot water to the boiler used to produce steam for the oven or the proofer of the line. This hot water can also be used for cleaning and for heating the building in the cold months.

New ovens can now be configured for maximum energy efficiency. Intelligent control system that communicates continuously with the central heating system is an example. Otherwise, heat recovery systems are in my opinion intrinsically the most economical energy savings solution. The concept is to install a heat exchanger directly into the exhaust gas of the oven. This recovered heat can be used to provide hot water to the boiler used to produce steam for the oven or the proofer of the line. This hot water can also be used for cleaning and for heating the building in the cold months.

TUNNEL OVENS TECHNOLOGIES

Now that all the options have been detailed, here comes the time to describe the different types of tunnel ovens in the bakery industry.

Current baking technologies are definitely not the same as the ones in these past decades. As an example, direct flame and direct resistance ovens have been switched by solutions much more effective, capable to bring energy savings and easy ways of monitoring.

DIRECT CONVECTION OVENS

This range of ovens, sometimes called impingement ovens, is based on forced direct convection. The first step of this solution requires to heat the air thanks to a heat exchanger connected to a burner or an electrical resistance. Then, hot air is directly blown inside the oven chamber for a direct contact between the product and the heated air. This technology is the same as direct fired forced convection except the fact that no combustion products pass into the baking chamber because a separate air circulation system is used. A much better solution in a health risks point of view. Convection is the transfer mode to bake.

This range of ovens, sometimes called impingement ovens, is based on forced direct convection. The first step of this solution requires to heat the air thanks to a heat exchanger connected to a burner or an electrical resistance. Then, hot air is directly blown inside the oven chamber for a direct contact between the product and the heated air. This technology is the same as direct fired forced convection except the fact that no combustion products pass into the baking chamber because a separate air circulation system is used. A much better solution in a health risks point of view. Convection is the transfer mode to bake.

CYCLOTHERMIC OVENS

A second concept is based on heated air flow system and radiation heat transfer. In that case, a first step consists in heating air passing through a heat exchanger connected to a burner or an electrical resistance. Then this heated air circulates through chambers all around the oven. Radiation is now the transfer mode to bake.

In details, cyclothermic ovens bake using heat coming from a heat exchanger connected to a gas burner or an electrical resistance and strong fans that circulate this heated air through plenum chambers in the oven. Hot air pass through tubes above and below the products transiting on the belt making heat radian conditions optimized to bake. Hot air then circulates back to the heat exchanger to be heated again and blown for a new cycle. Air circulation is monitored thanks to temperature sensors and air valves. Oven temperature is therefore easy to drive with a high level of accuracy.

In details, cyclothermic ovens bake using heat coming from a heat exchanger connected to a gas burner or an electrical resistance and strong fans that circulate this heated air through plenum chambers in the oven. Hot air pass through tubes above and below the products transiting on the belt making heat radian conditions optimized to bake. Hot air then circulates back to the heat exchanger to be heated again and blown for a new cycle. Air circulation is monitored thanks to temperature sensors and air valves. Oven temperature is therefore easy to drive with a high level of accuracy.

These types of ovens are now well known for their benefits: quality, flexibility and reliability. In addition, no combustion products, bringing health risks, pass into the baking chamber making this baking solution very safe.

Cyclothermic thermal oil ovens:

Here is a specifi range of cyclothermic tunnel ovens. Thermal oil serves as a heat conducting medium for the transfer of energy between a thermal oil boiler and the oven. Its properties ensure an effective transfer of heat energy while also functioning as a good accumulator of heat. As well as  cyclothermic oven using air as a heat conducting medium, thermal oil flows through the upper and lower radiators of the oven. The upper radiators directly heat the top of the oven chamber, whereas the lower radiators generate heat under the belt of the oven.

cyclothermic oven using air as a heat conducting medium, thermal oil flows through the upper and lower radiators of the oven. The upper radiators directly heat the top of the oven chamber, whereas the lower radiators generate heat under the belt of the oven.

Due to the minimal difference between the temperatures of the oil itself and that of the oven chamber gentle radiant heat is achieved. The best way to guarantee stable baking curves and temperature distribution lead to reproducible baking results. Thermal oil heating systems are operating highly economical and optimizes production costs. Therefore, it is an environmentally friendly solution. But this solution requires extra costs such as a boiler room and a thermal oil insulated ring.

INNOVATION: HYBRID SOLUTIONS

This third and last range of tunnel ovens is the smartest one.  A way to bake by combining all these different heat transfer technologies. Depending on the needs of the products, heat transfer solution can change during the baking time, at times using direct convection, then radiation or both at the same time. And in addition the benefits of conduction heat transfert coming from the heated belt. It is now very easy to understand how much efficiency, quality, and accuracy such a solution can bring to bake. Settings to monitor the oven are now unlimited. A baking time for product is now divided in two, three or more stages with dedicated settings to the first seconds in the oven, to the mid-point stage and to the last minutes in the oven…

A way to bake by combining all these different heat transfer technologies. Depending on the needs of the products, heat transfer solution can change during the baking time, at times using direct convection, then radiation or both at the same time. And in addition the benefits of conduction heat transfert coming from the heated belt. It is now very easy to understand how much efficiency, quality, and accuracy such a solution can bring to bake. Settings to monitor the oven are now unlimited. A baking time for product is now divided in two, three or more stages with dedicated settings to the first seconds in the oven, to the mid-point stage and to the last minutes in the oven…

It is time to introduce the hybrid baking solution from MECATHERM: M-TA OVEN, and Marie LAISNE, product manager, who will give more details about this innovation.

Baking impacts various characteristics of the product like its shape, color, thickness of the crust, texture, taste, and softness, …Then, setting a baking profile for each product is crucial to obtain the expected quality of the final products. In order to meet this precision need for a wide range of products, the M-TA oven has been developed.

The M-TA oven offers a technology which is unique on the market: for each independent heating chambers, the baker and patisserie chef can choose between 6 heating transfer modes and for each configuration, set the heating intensity.

Radiation, convection or a combination of both are available on top. A patented « mobile hearth » system enables to choose between radiation or convection on hearth.

Radiation, convection or a combination of both are available on top. A patented « mobile hearth » system enables to choose between radiation or convection on hearth.

This energy management associated to a fine precision of hygrometry inside the heating chamber enables the setting of a tailor-made baking curve for a wide range of products from bread to pastry products, to brioche products until patisserie and food products.

Customer testimonial

Written by : Marie LAISNE, MECATHERM product manager.

FOCUS ON MECATHERM COMPANY

Founded in 1964, MECATHERM is a French company located in the Est of France. MECATHERM has expanded by integrating GOUET company in 2009, a way to become a strong bakery oven manufacturer leader all around the world. Production is carried out in two sites in France. MECATHERM sales offices are located in three countries, France, Mexico and Malaysia and foreign branches in the United States in Atlanta and Georgia. MECATHERM company is headed by Oliver SERGENT and employs more than 400 people.

MECATHERM scope of solutions is very large and revolves around many products such as crusty breads (baguettes, rolls and derivates), soft breads (sandwiches and toasted breads, buns, bagels…), flat breads, sweet products (cakes, pastries, macarons, pies…), and more.

MAKE UP LINES:

MECATHERM make up lines scope of supply is composed of dividing and moulding machines.

Such as the MN-S dividing machine, dedicated to high hydrated dough:

PROOFERS, coolers and freezers:

MECATHERM handling solutions are tailored to proofers, coolers and freezers steps.

Such as the MU-B handling system, the New MECATHERM handling reference:

TURNKEY SOLUTIONS:

MECATHERM can provide turnkey solutions in a complete production line scope or in a large scope of a plant project.

AND MORE:

Here is the link of the MECATHERM web site to find out the complete scope of supply and solutions of the company.

TO CONCLUDE…

Each industrial processing diagram step in the bakery industry is important, that is why it is crucial to focus on each one to achieve the best level of industrial efficiency. However, this diagram is composed of key stages. Mixing with an accurate control on dough temperature is one of them, baking is another one.

Baking solutions by using tunnel ovens in the bakery industry are numerous. A question comes easily: which one is the best? As usual when I have to answer such a question, regarding ovens but not only, I am used to saying that the best solution is the dedicated one to your needs. That is to say that a solution can be the one in one hand but inappropriate in another one. For one major reason: industrial needs and expectations are specific in each situation. That is why I always focus with my clients on the right definition of their needs to find out then the best tailor-made technical solutions.

To conclude, I would like to write a few words to MECATHERM team. I have been sharing, still today, a lot of industrial projects in the bakery industry with many people working in this company. We keep on working with the same passion for the dough and the products. But I realize that we do so with the same sense of innovation and goal to find new solutions for tomorrow. So, hello to every one!

This article has been written by Ronan Le Bourhis, founder of Hopi consulting, engineering dedicated the baking industry. Discover more articles in Hopi consulting blog.